Rongke was established amidst the backdrop of rapid technological development, always adhering to the vision of empowering technology enterprises with low-carbon intelligent manufacturing and shouldering the mission of creating full lifecycle value for customers. Taking listening to customer needs as the starting point, the company adheres to the principles of precise design and high-quality processes, integrating the concepts of safety first, and prioritizing quality and cost into every project. Through digital delivery methods, it ensures that key aspects are realized one by one, striving to become a leading enterprise in "creating full lifecycle value for critical facilities" in high-tech factories and data centers.

The company boasts a large and professional talent pool, with a total workforce exceeding 600 employees. Among them, there are 18 in the operational decision-making level, 32 in general functional roles, 33 in software R&D, 75 in professional design, 300 in executive management, 135 in manufacturing, and 7 in marketing. It serves over 300 customers, including more than 30 leading industry clients and 12 renowned scientific research institutes, with single-project engineering investments from leading clients ranging from 1 to 15 billion.

Rongke adopts a matrix-style flat management structure and has constructed a customer-centric "Heaven-Earth-Tree" organizational framework. "Heaven" represents corporate culture and values, providing spiritual guidance for the company's long-term development; "Earth" is the operational middle platform, offering solid support for project execution; and "Tree" consists of BU + LTC business units, serving as the core force for business expansion and project implementation. Meanwhile, the company has established a Shareholders' Meeting, Board of Directors, and Board of Supervisors, implements a CEO responsibility system, and has set up a Party branch to ensure the correct direction of corporate development.

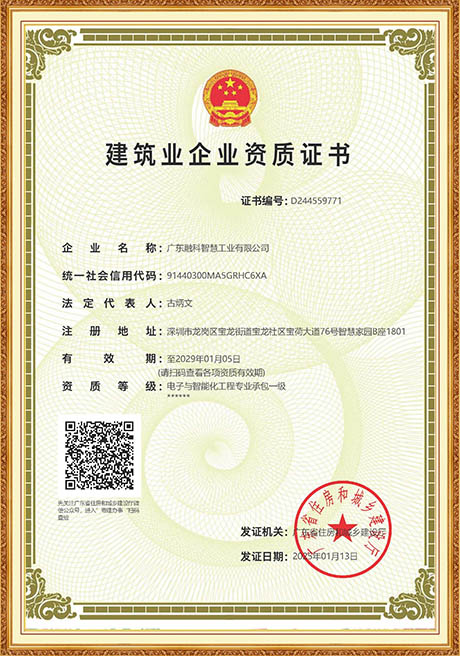

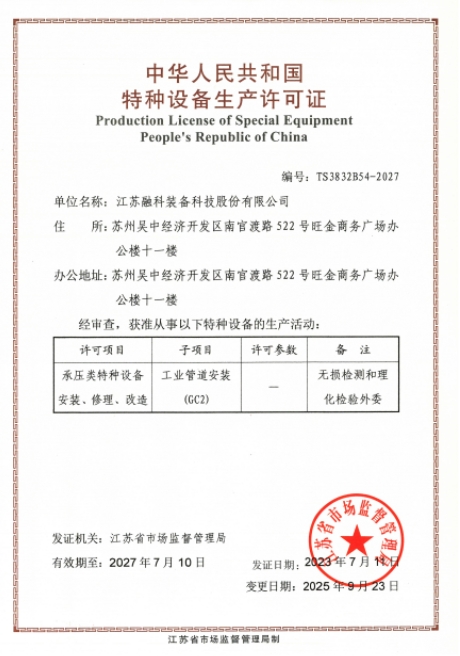

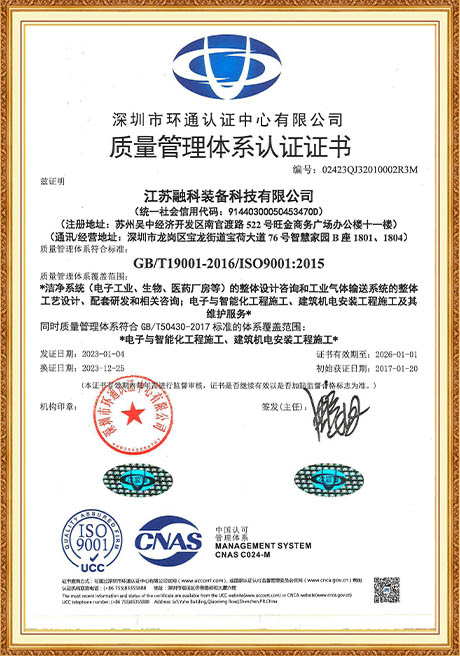

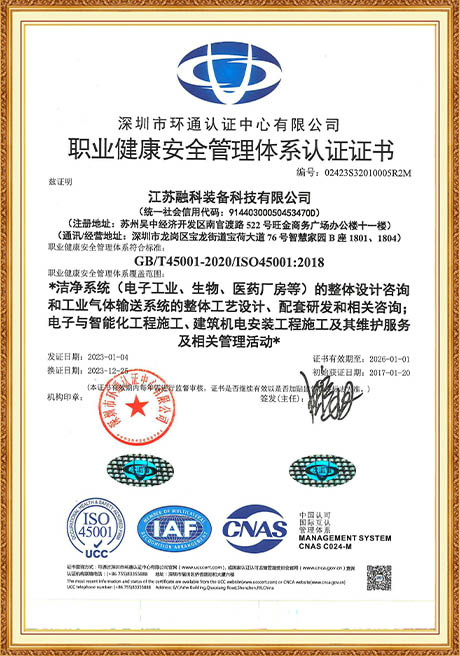

With exceptional technological prowess and strict quality management, the company has obtained numerous authoritative qualifications and certifications, including Grade I Professional Contracting for Mechanical and Electrical Engineering, Grade I Professional Contracting for Electronic and Intelligent Engineering, and a Special Equipment Production License - Pressure Pipeline Installation GC2 Level. It has also been recognized as a National High-Tech Enterprise, a Well-Known Enterprise for Excellent Service Quality, and an AAA Credit Enterprise, and has passed certifications for quality, environmental, and occupational health management systems. Additionally, its equipment has received SEMI S2/S8 and EN certifications, and the company holds over 100 patent technologies and software copyrights, providing solid technical support for the smooth implementation of projects.

Rongke is a global partner of Siemens, holding a unique position in the electronic semiconductor industry as the sole solution partner in China. The company has established multi-level cooperative relationships with Siemens, including Siemens Automation Drive Certified Integrator - Platinum Level (domestically issued), Siemens Solution Partner - Global Certification (issued in Germany), Siemens Control Cabinet Certified Partner, and Siemens VIP Customer Certificate. These collaborations have not only enhanced the company's technological capabilities and market competitiveness but also provided strong support for better serving customers.

Rongke has led the development of digital engineering specifications for the electronics industry and has been the primary or contributing editor for a total of 21 national and industry standards, including the "Technical Specification for Integrated Automation Engineering in Electronic Industry Factories GB," "Building Information Modeling Standard for Electronic Engineering," "Intelligent Standard for Support Systems in the Electronic Industry," "Design Specification for Lithium-Ion Battery Factories," and "Digital Technology Standard for Pipeline Engineering in the Electronic Industry GB," making significant contributions to the industry's development.

The company possesses advanced technologies and tools, including the IPD Integrated Product Development Platform, ISPD Integrated Service Delivery Platform, and IFS Integrated Financial Services. The IPD platform focuses on customer needs, addresses pain points, provides precise and professional data, and optimizes customer requirements; the ISPD platform constructs an end-to-end, efficient digital delivery system through AI + BIM, CRM customer management, simulation, and other systems, ensuring quality and efficiency while reducing non-conformance costs; the IFS platform includes a cost database and builds an efficient SCM supply chain resource and financial services system to ensure fair transactions.

Rongke has numerous high-quality customers, including Guangdong Yuexin, Maxscend, Shandong Tianyue, Liyang Co., Ltd., Shenzhen Powersemi, Fenghua Advanced Technology (Group), Guangdong Nano Institute, the 48th Institute of China Electronics Technology Group Corporation - Changsha, Shanghai Linzhong, Shanghai Cambridge, Zhuhai Jishi, JCET, Tianma Micro-electronics, and Company H. With its outstanding services and high-quality projects, the company has received 20 Best Supplier Awards, 29 Best Project Awards, and 7 Best Team Awards, winning high recognition from customers and widespread acclaim in the market.

Looking ahead, Rongke will continue to adhere to its customer-centric philosophy, prioritizing safety, quality, and cost, and continuously enhance its technological capabilities and service levels. Through continuous innovation and optimization, it will provide technology enterprises with superior and efficient low-carbon intelligent manufacturing solutions, helping customers maximize full lifecycle value. In its future development, Rongke will actively expand domestic and international markets, strengthen in-depth cooperation with partners, jointly promote industry development and progress, and become a global leader in low-carbon intelligent manufacturing for technology enterprises.