Key Features: Located in Huizhou, this project's air conditioning water demand is primarily for process dehumidification and air conditioning, providing 24/7 cooling, 360 days a year. The air conditioning system provides cooling for the electrode + assembly building and the active building, respectively. The project combines a high-efficiency machine room with a cold storage system, with a cooling capacity requirement of 8,636 RT/h, and a water supply temperature adjustable within a range of 4-10°C. The total cold storage design capacity is 60,000 RT/h. A load model, equipment energy consumption model, and optimization control model were developed based on the project's actual conditions. The annual peak load is 6,000 RT, and the annual minimum load is 2,160 RT.

Pengcheng National Laboratory

Project: Engineering Design, Procurement, and Construction (EPC) for the Pengcheng Experimental Heterogeneous Optoelectronic Chip Research Platform Site Construction

Location: Shenzhen, Guangdong

Date: 2023

Project Size: RMB 30 million

Delivery Time: 180 days

Service Scope: Purification and Interior Design, Water Supply and Drainage, Electrical, Purification and HVAC, Intelligent Systems, Process Specialty Gases, Process Bulk Gases, Process Pure Water Piping, Process Wastewater Piping, Process Waste Gas, and Process Waste Gas

Key Features: The total installation area for this project is approximately 2,500 square meters, including 580 square meters of Class 100 purification area and 220 square meters of Class 10 purification area. Preliminary design and construction will be based on process production requirements.

Zhejiang Cambridge Communication Equipment Co., Ltd.

Project: Cleanroom Renovation Project for the Jiashan Plant of Zhejiang Cambridge Communication Equipment Co., Ltd.

Location: Jiaxing, Zhejiang

Date: 2024

Investment: RMB 40 million

Delivery Time: 120 days

Service Scope: Cleanroom renovation, water supply and drainage, electrical, cleanroom HVAC, intelligent systems, process bulk gas, process pure water piping, process wastewater piping, and process waste gas

Shanghai Linzhong Electronic Technology Co., Ltd.

Project: Shanghai Linzhong Electronics New Factory Project, Cleanroom Renovation Project

Location: Shanghai

Date: 2023-2024

Project Size: 27 Million RMB

Delivery Time: 120 Days

Service Scope: Cleanroom renovation, water supply and drainage, electrical, cleanroom HVAC, intelligent systems, bulk process gas, process wastewater piping, process exhaust gas, and secondary distribution

Dongguan Jingcai Optics Co., Ltd.

Project: New Factory Building, High-Efficiency and Energy-Saving Plant System Engineering Project

Location: Dongguan, Guangdong

Project Size: RMB 29.27 million

Delivery Time: 120 days

Guangdong Nano Intelligent Manufacturing Industry Innovation Center Co., Ltd.

Project: National Nano Intelligent Manufacturing Industry Innovation Center Micro-Nano Processing Platform Construction Project Phase II Design and Construction General Contracting Project

Location: Guangzhou, Guangdong

Date: 2020-2024

Project Size: RMB 78 million

Delivery Time: 180 days

Service Scope: Cleanroom renovation and design and construction of cleanroom-related electromechanical systems (including fire protection, air conditioning, pure water, wastewater, exhaust gas, waste liquid systems, power, FMCS, bulk gas, specialty gas, and secondary distribution).

Xiamen Tianma Optoelectronics Co., Ltd.

Project: FMCS Plant Monitoring System Engineering for Xiamen Tianma Optoelectronics Co., Ltd.'s 8.6th Generation New Display Panel Production Line

Location: Xiamen, Fujian

Date: 2023

Project Size: RMB 45 Million

Delivery Time: 524 Days

Service Scope: Automatic FMCS and Security Systems

Shanghai Dingtai Jiangxin Technology Co., Ltd.

Project: FMCS System Engineering for the F16-01 Plot Project in the Lingang Heavy Equipment Industrial Zone, Shanghai Dingtai Jiangxin Technology Co., Ltd.

Location: Shanghai

Date: 2022

Project Size: RMB 22.36 million

Delivery Time: 199 days

Service Scope: Automatic FMCS System

Wuhan Huaxing Optoelectronics Technology Co., Ltd.

Project: FMCS System Engineering for the 6th Generation LTPS Semiconductor New Display Device Production Line Expansion Project

Location: Wuhan, Hubei

Date: 2022

Project Size: RMB 11.99 million

Delivery Time: 230 days

Service Scope: Automatic FMCS System

Runpeng Semiconductor (Shenzhen) Co., Ltd.

Project: Runpeng Semiconductor 12-inch Integrated Circuit Production Line FMCS Automation Project

Location: Shenzhen, Guangdong

Date: 2023

Project Size: 18 million yuan

Delivery Time: 180 days

Service Scope: Automatic FMCS System

Key Features: The Runpeng Semiconductor 12-inch Integrated Circuit Production Line project has a total investment of 22 billion yuan. The project focuses on analog specialty processes above 40 nanometers. The products are primarily used in automotive electronics, new energy, industrial control, consumer electronics, and other fields.

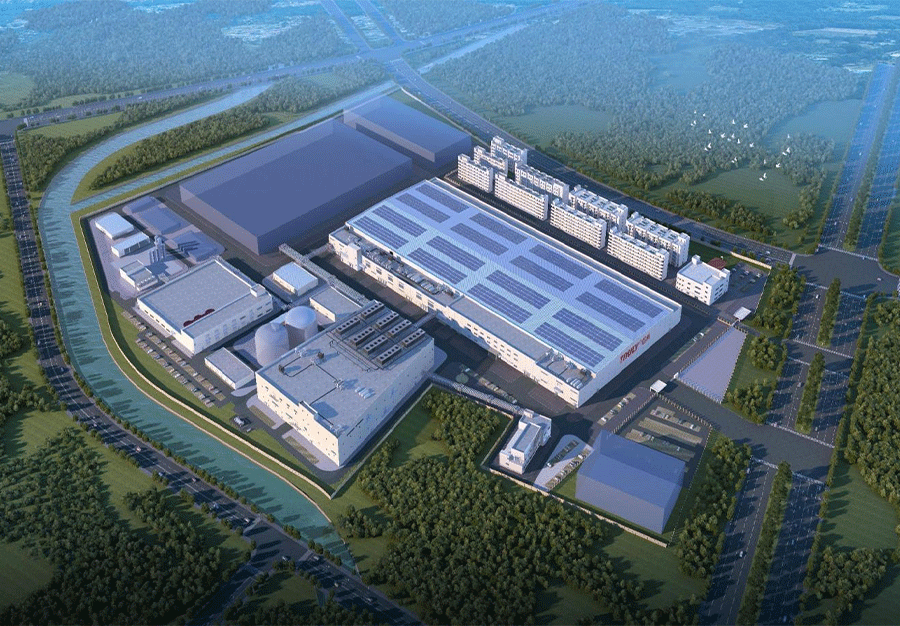

Tongwei Solar (Meishan) Co., Ltd.

Project: High-Efficiency Crystalline Silicon Solar Cell (Phase IV) Supporting Basic Weak Current System Project

Location: Sichuan

Date: 2023-2024

Project Size: RMB 64 Million

Delivery Time: 100 Days

Tongwei Solar (Pengshan) Co., Ltd.

Project: Global Innovation Base (Phase I) S1 Workshop and Auxiliary Building Weak Current System Engineering

Location: Sichuan

Date: 2023

Project Size: RMB 10.6 Million

Delivery Time: 100 Days

Service Scope: Automatic Control, FMCS, and Security Systems

Key Features: The first phase of the project, with a planned total investment of RMB 6 billion, will construct a high-efficiency crystalline silicon solar cell intelligent manufacturing plant and supporting facilities such as environmental protection and warehouses. Upon completion, it will have an annual production capacity of 16GW, making it the largest high-efficiency crystalline silicon solar cell intelligent plant in the industry in terms of unit investment intensity, single-unit production capacity, and leading process technology.

Zhejiang University — Zhejiang Chuangxin Integrated Circuit Co., Ltd.

Project: Renovation Project of the Micro-Nano Ultra-Clean Laboratory Wide Bandgap Semiconductor Platform at the Zhejiang University Hangzhou International Science and Innovation Center (Startup Area – Scenario Valley) – Design and Construction Integration Project

Location: Hangzhou, Zhejiang

Duration: 2020

Project Scale: RMB 76 million

Delivery Period: 150 days

Scope of Services: Cleanroom renovation, plumbing and drainage, electrical systems, cleanroom HVAC, intelligent control systems, process specialty gas, process bulk gas, process ultrapure water pipelines, process wastewater pipelines, process exhaust systems, and FMCS automation system.

Main Features:

Main Product: Wide Bandgap Semiconductor Experimental Platform

The project involves renovation and construction of the LAB and CUB to create a functional space for the smooth operation of the wide bandgap semiconductor experimental platform. It also includes the construction of outdoor pipe corridors, connecting corridors, material warehouses, a new Class A chemical warehouse, gas rooms, and auxiliary buildings. The work covers cleanroom-related MEP installation, general MEP installation, and facility systems engineering such as ultrapure water, wastewater, exhaust gas, and gas/chemical supply systems. The main clean research area and utility area cover approximately 3,000 square meters. System design and main system capacity fully meet the process requirements of the research platform.

Zhejiang University — Zhejiang Chuangxin Integrated Circuit Co., Ltd.

Project: Kechuang CMOS 12-Inch Pilot R&D Platform Project

Location: Hangzhou, Zhejiang

Duration: 2021

Project Scale: RMB 470 million

Delivery Period: 360 days

Scope of Services: Cleanroom renovation, plumbing and drainage, electrical systems, cleanroom HVAC, intelligent control systems, process specialty gas, process bulk gas, process ultrapure water pipelines, process wastewater pipelines, and process exhaust systems.

Main Product: 12-Inch CMOS Integrated Circuit Chips

The project involves the construction of newly built LAB1 and CUB facilities to create a smooth-operating micro-nano ultra-clean laboratory platform. It also includes the construction of outdoor pipe corridors, connecting corridors, material warehouses, a new Class A chemical warehouse, gas rooms, and auxiliary buildings. The work scope includes cleanroom-related MEP installation, general MEP installation, and facility systems engineering such as ultrapure water, wastewater, exhaust gas, and gas/chemical supply systems. The main clean research area and utility area cover approximately 30,000 square meters. System design and main system capacity fully meet the process requirements of the research platform.

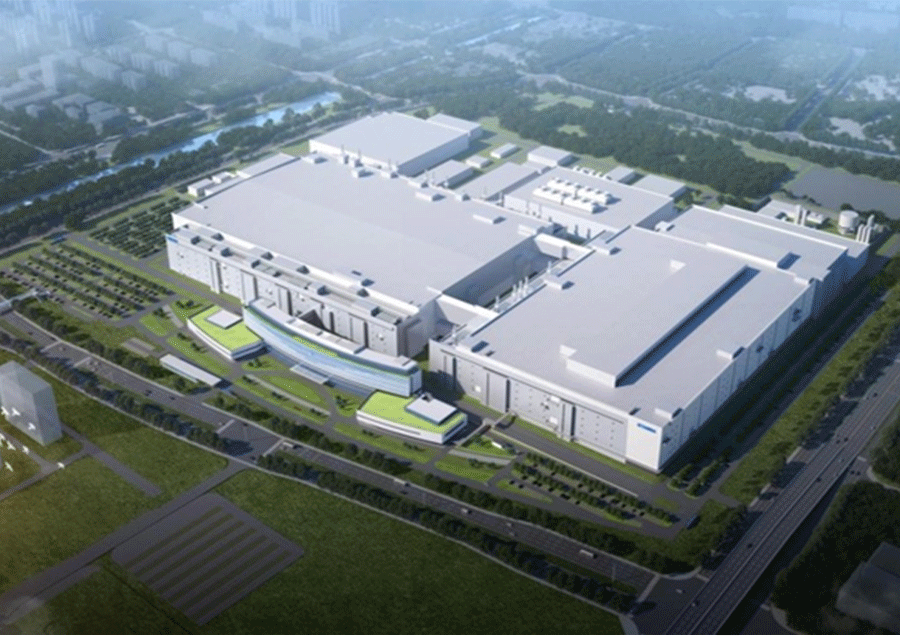

Yangtze Memory Technologies Co., Ltd. (YMTC)

Project: National Memory Base Project (Phase I) – FAB2 and Supporting Facilities MEP Design, Procurement, and Construction Engineering

Location: Wuhan, Hubei

Duration: 2018–2024

Project Scale: RMB 140 million

Delivery Period: 730 days

Scope of Services: FMCS automation and security systems, IT data center expansion

Main Features: The factory site covers a total area of 1,717 acres, with a planned total construction area of approximately 1.7 million square meters. The project is being developed in three phases, with an overall plan including three 12-inch 3D NAND memory chip fabrication plants (FAB1, FAB2, and FAB3). Each plant features a cleanroom production area of 68,000 square meters and a production capacity of 100,000 wafers per month.

Shanghai EBU Semiconductor Co., Ltd.

Project: EBU Semiconductor Advanced Packaging Production Line Renovation Project

Location: Baoshan, Shanghai

Duration: 2022–2023

Project Scale: RMB 110.49 million

Delivery Period: 240 days

Scope of Services: MEP systems, specialty gas systems, ultrapure water systems, wastewater, exhaust gas, and waste liquid treatment systems, as well as secondary distribution.

Main Features: The project occupies a total land area of approximately 15,419.5 square meters, with a renovation area of 11,273.6 square meters. It involves the construction of an advanced wafer-level integrated circuit packaging production line with an annual capacity of 720,000 units. The project, with a total investment of RMB 746 million, is funded by Shanghai EBU Semiconductor Co., Ltd. It is located within the Shanghai Robotics Industrial Park, covering 23.01 acres, and includes the establishment of a fan-out wafer-level packaging and testing production line, as well as an advanced silicon photonics wafer-level packaging process experimental platform jointly developed with the Institute of Microelectronics of the Chinese Academy of Sciences.

Shanghai TYSiC Semiconductor Materials Co., Ltd.

Project: Chemical System Design and Construction, and FMCS Facility Monitoring System Engineering for the Shanghai TYSiC Silicon Carbide Semiconductor Materials Project

Location: Shanghai

Duration: 2022

Project Scale: RMB 40 million

Delivery Period: 250 days

Scope of Services: Chemical system engineering, FMCS system, high-efficiency equipment room, and energy management.

Main Features: The project is located in the Lingang area of Shanghai, with a planned investment of RMB 2.5 billion. It covers an area of 100 acres and has a total construction area of approximately 95,000 square meters. More than 1,000 sets of production equipment will be added. Upon completion, the facility will primarily produce 6-inch conductive silicon carbide semiconductor materials. When operating at full capacity, it is expected to achieve an annual production of 26,000 conductive silicon carbide crystal ingots, corresponding to 300,000 substrate products.

Jiangsu Maxscend Microelectronics Co., Ltd.

Project: Slurry Supply System Installation and Engineering for the Xinzhuo Semiconductor Industrialization Construction Project

Location: Wuxi, Jiangsu

Duration: 2021

Project Scale: RMB 8.58 million

Delivery Period: 138 days

Scope of Services: Slurry supply system engineering

Main Features: The project covers an area of approximately 100,000 square meters, with a total construction area of about 150,000 square meters and a construction period of 14 months. This project is a turnkey engineering contract for the slurry supply system, including the control and supply system and SCADA (supervisory control and data acquisition) system integration. It encompasses the construction and operational testing of the 1F raw material delivery system, acid mixing and dilution system, as well as the complete establishment of the slurry supply system.

Hefei Chiny Optoelectronics Co., Ltd.

Hefei Chiny Optoelectronics Co., Ltd.

Project: Special Gas Engineering and Chemical System Engineering for the Hefei Chiny Optoelectronics 8.5th Generation and Below High-Precision Photomask Project

Location: Hefei, Anhui

Duration: 2019

Scope of Services: Special gas engineering, chemical system engineering

Main Features: The project is located in the Xinzhang District of Hefei City, with a total investment of RMB 736.0035 million and a construction area of 45,288 square meters.

Construction Content: Six types of gases, including gas supply equipment and pipelines, air compression systems, and other supporting facility management systems, as well as six sets of chemical supply system engineering.

Guangdong-Hong Kong-Macao Greater Bay Area National Institute for Nanotechnology Innovation

Project: Phase I of the R&D Platform of the Greater Bay Area Institute for Nanotechnology

Location: Guangzhou, Guangdong

Duration: 2020

Project Scale: RMB 6.12 million

Delivery Period: 90 days

Scope of Services: Specialty gas system engineering, automation system engineering

Main Features: The project covers a total land area of approximately 29,000 square meters, with a total construction area of about 51,000 square meters. It is the first IDM chip project in Guangzhou and will mainly produce RF front-end filters for 5G mobile phones after completion.

Construction Content: 14 types of gases, including specialty gas equipment and pipelines, gas monitoring systems, exhaust treatment systems, and supporting facility management systems, as well as automation system engineering.

Dongguan Tianyu Semiconductor Technology Co., Ltd.

Project: FMCS System Engineering for Guangdong Tianyu Semiconductor Co., Ltd. Headquarters and Manufacturing Center Construction Project (Phase I & II)

Location: Dongguan, Guangdong

Duration: 2023–2024

Project Scale: RMB 50 million

Delivery Period: 362 days

Scope of Services: FMCS automation system, gas system engineering (bulk gas and specialty gas)

Main Features: The Guangdong Tianyu Semiconductor Co., Ltd. Headquarters and Manufacturing Center Project has a total investment of RMB 8 billion, covering an area of approximately 165 acres with a total construction area of about 240,000 square meters. The facility is designed for the production of 6-inch and 8-inch silicon carbide (SiC) epitaxial wafers, with an expected annual capacity of 1.5 million wafers.