Business Introduction

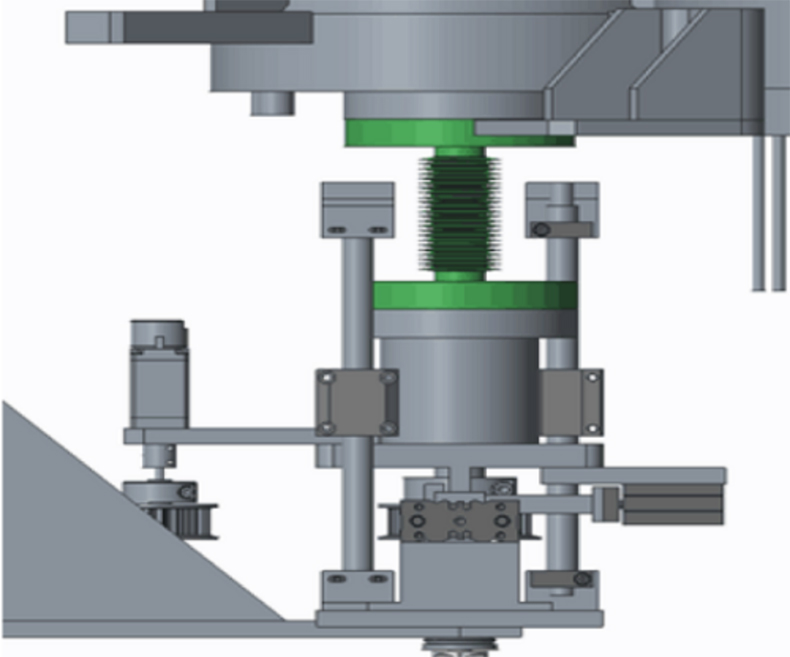

Precision Component

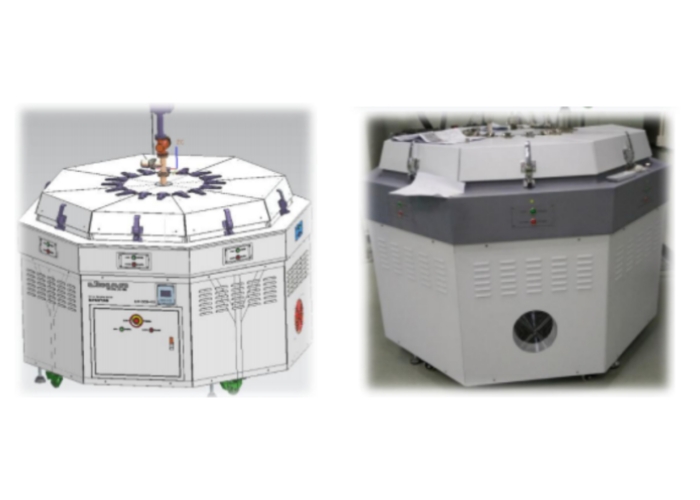

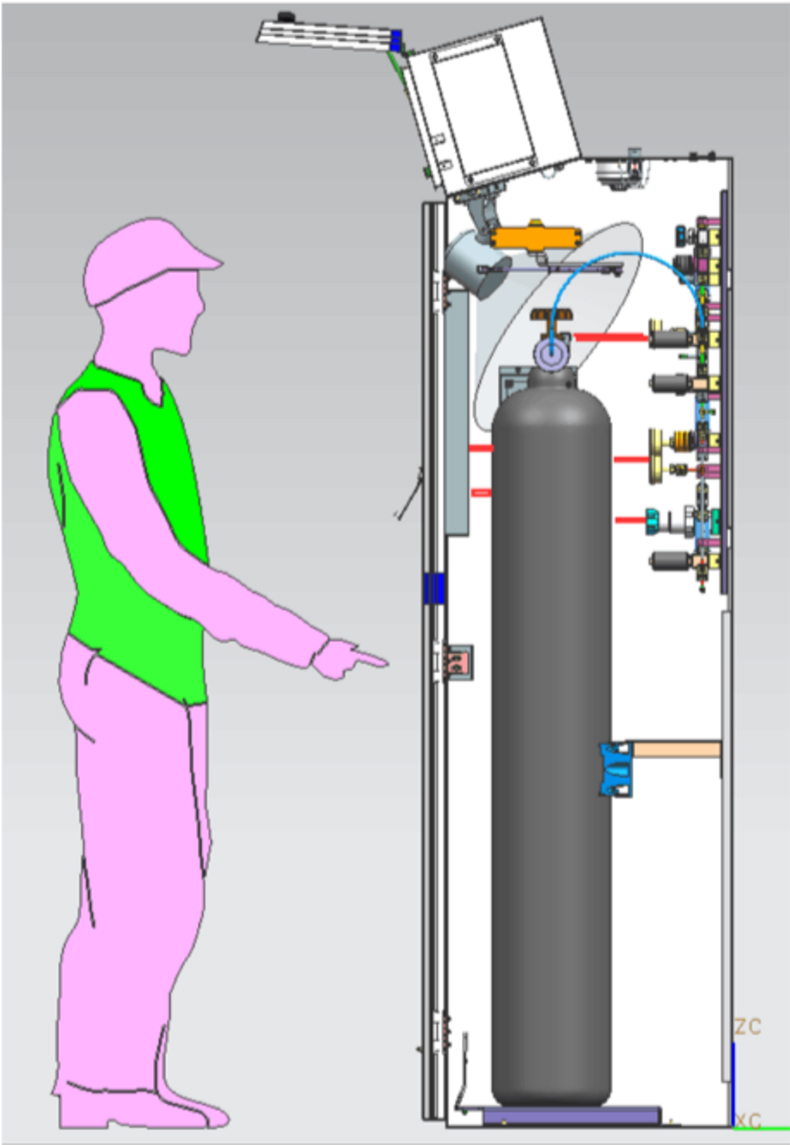

Gas & Chemistry and Intelligent Control Equipment

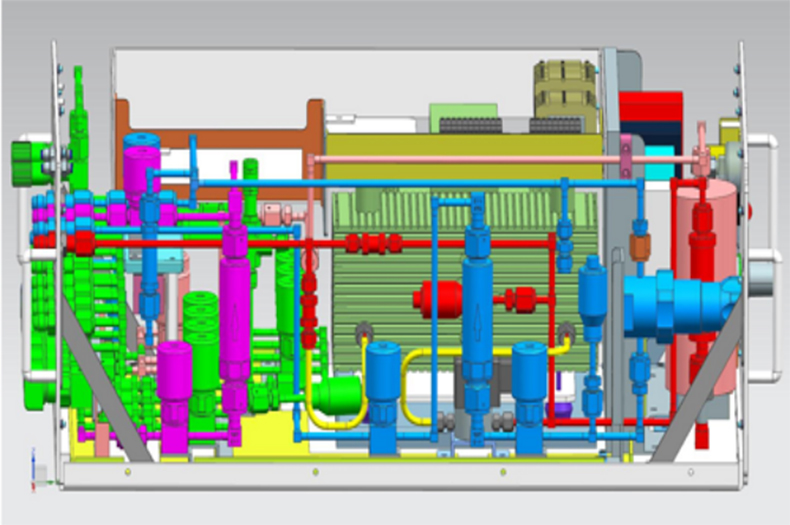

Process Module

Customized Product…

Equipment Level

Component Level

Component Level

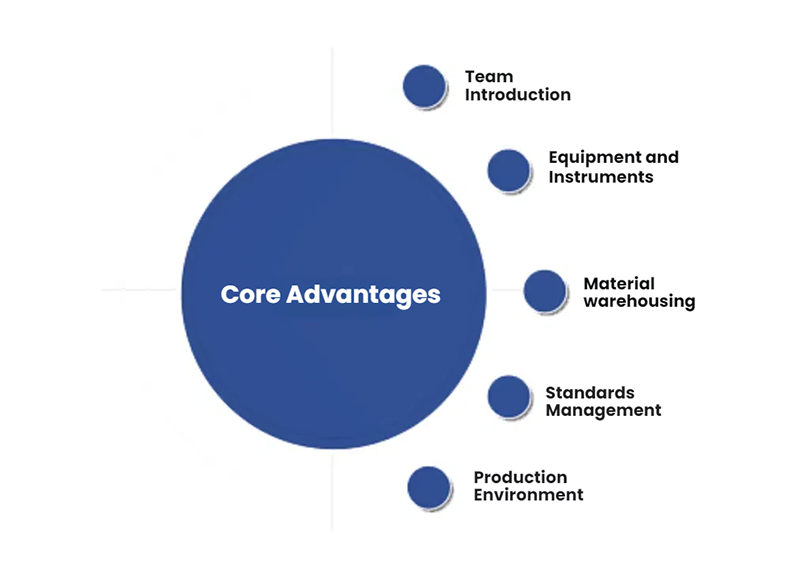

Core Competencies

"Technical Specifications for Integrated Automation Engineering for Electronics Industrial Plants," "Electronic Engineering Building Information Modeling Standard," "Electronic Industry Support System Intelligentization Standard," "Lithium-ion Battery Plant Design Specification," "Central Air Conditioning Room Engineering Energy Efficiency Rating and Limit Value Standard"

We provide consulting and design services for the electronics industry, critical infrastructure integration, digital software and database services, component and complete equipment manufacturing (domestic substitution), and operations and maintenance support. With over 810 experienced engineers, we offer one-stop solutions for critical infrastructure, creating value for our customers. In the past five years, we have served over 360 clients and completed over 3,000 projects.

Standard Equipment

Standard Equipment

1. Manufactured in strict accordance with SEMI certifications.

2. Over 15 years of equipment manufacturing experience.

3. Standard digital design – what you see is what you get.

4. Equipment components are sourced from world-class manufacturers, and custom brands are accepted.

5. Highly efficient, energy-efficient, and safer and more reliable.

Customized Equipment

1. Experienced engineers with diverse backgrounds ensure rapid response to customer customization needs

2. Technical and resource support from Shanghai Electronic Engineering Design Institute and Rongke Technology

3. Advanced manufacturing equipment, a cleanroom production environment, and testing equipment

Core Strengths

Leveraging the strengths of a well-organized team structure, comprehensive production equipment, a large inventory of conventional materials, and a cleanroom production facility, coupled with a robust management system, we offer rapid production and supply of proprietary specialty gas and chemical delivery and mixing equipment, continuously updated and improved. We assist manufacturers (research institutions) in developing and manufacturing product requirements for specialized systems and technologies, providing comprehensive services from initial product testing to mass production.

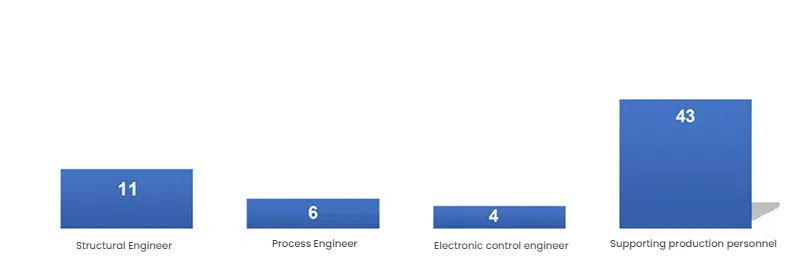

The team's core members are all from domestic and international research institutions and equipment manufacturers. 50% of them have over ten years of industry experience, possessing both professional theoretical knowledge and extensive practical experience.

Design capabilities

3D simulation capabilities

Utilize 3D simulation during the product design phase to refine the design and simulate all equipment structures.

1. Detect collisions and interferences during the design phase to effectively ensure design accuracy.

2. Perform mechanical analysis on load-bearing structural components to ensure their strength and enhance safety.

3. Improve the accuracy of equipment design and prevent unnecessary redundant structures.

3D modular design

Utilizing CFD (Computational Fluid Dynamics) simulation software enables precise calculation of key fluid component design parameters, effectively ensuring design reliability and accuracy.