Our Market

Integrated Circuits

Integrated circuit manufacturing technology is highly sophisticated and the processes are extremely complex, placing stringent demands on the stability of equipment and materials. Raycom Technology has a comprehensive and in-depth understanding of the IC industry and is well-positioned to provide ultra-pure electronic materials, factory systems, and related complete solutions. Leveraging our extensive experience partnering with leading semiconductor companies, we help customers achieve world-class performance and a rapid return on investment.

Flat Panel Displays

Raycom Technology leverages its expertise in ultra-high-purity gas and high-flow gas supply to provide high-level support to panel manufacturing customers. Raycom Technology's advanced factory systems offer expert operations and maintenance management services throughout the entire project lifecycle, helping customers' panel fabs achieve world-class performance and a rapid return on investment.

Semiconductor Lighting

The Rongke Gas Division provides ultra-high-purity gases for epitaxy and chip processing, including specialty gases, bulk gases, clean air compression, vacuum, and exhaust gas treatment systems, life safety monitoring systems, as well as value-added services such as rapid response, equipment maintenance, and TGCM.

Our Advantage

Main Design Systems

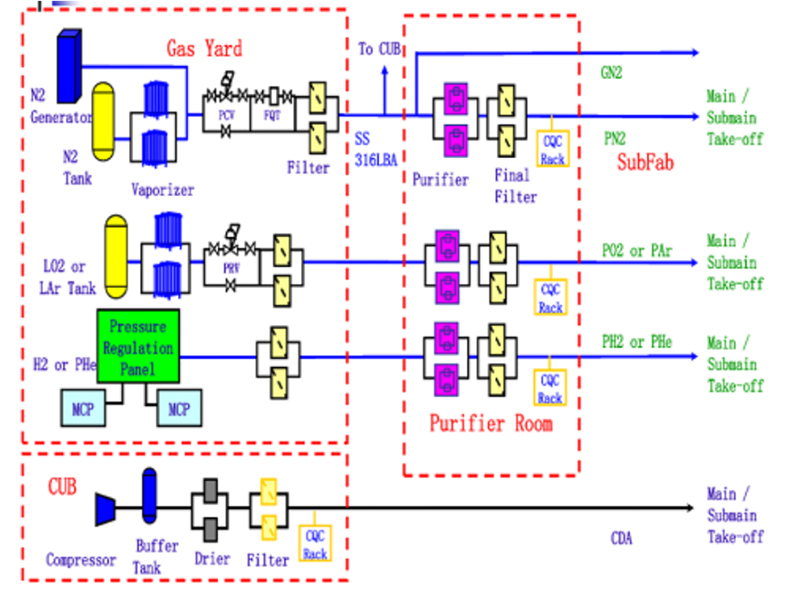

Specialty Gas Systems

Bulk Gas Systems

Exhaust Gas Treatment Systems

GDS & GMS Systems

Overall Effect

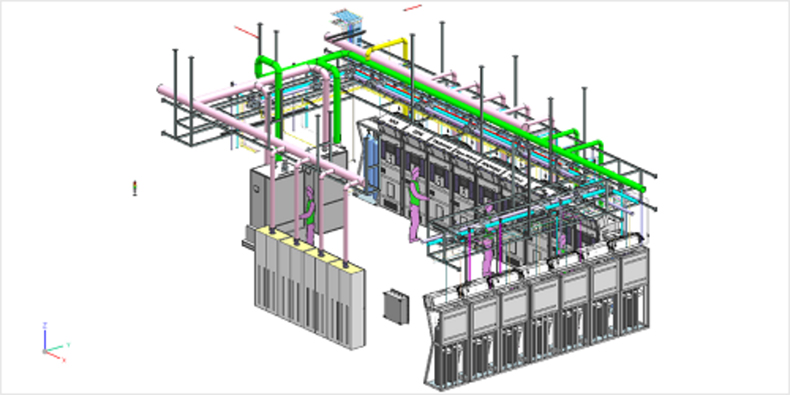

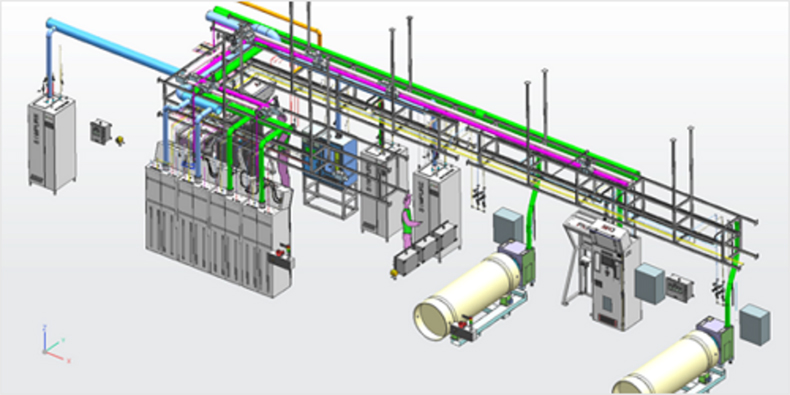

Optimize system configuration based on production process requirements. Using digital PID and construction drawing design, the requirements of various disciplines are updated in real time, providing customers with a streamlined, standardized, and fully standardized engineering management system and digital design results.

Advanced technology breaks the traditional shackles of individual skill levels determining overall engineering quality. The initial design perfectly delivered the final results, significantly reducing overall project costs, accelerating the project schedule, and ensuring quality. The overall technical level is at the forefront of the electronics industry.

Specialty Gas Supply System

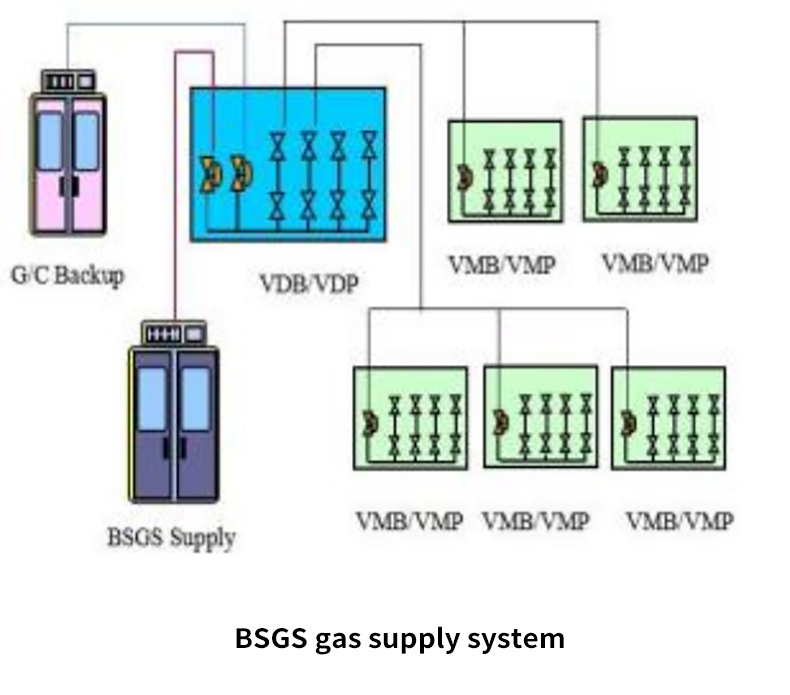

Bulk Gas Supply System

Exhaust Gas Treatment System

Gas Detection and Monitoring System

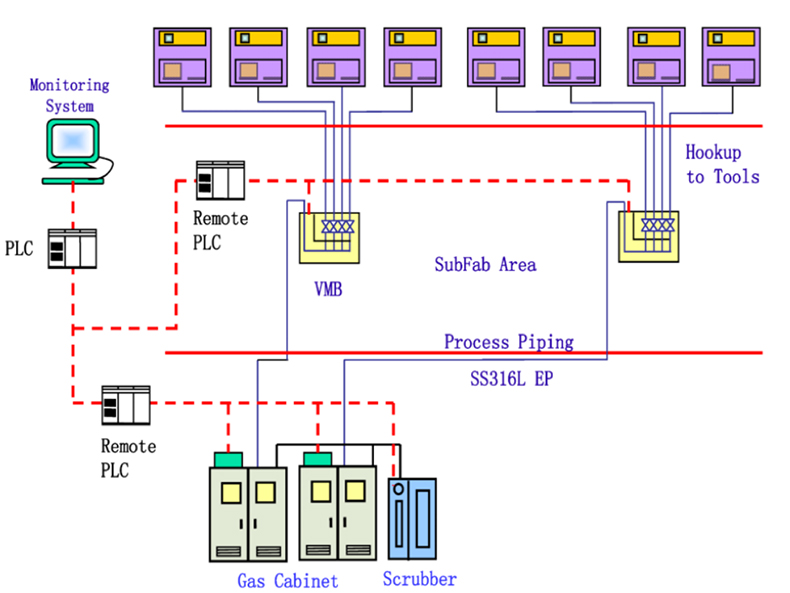

Monitoring System

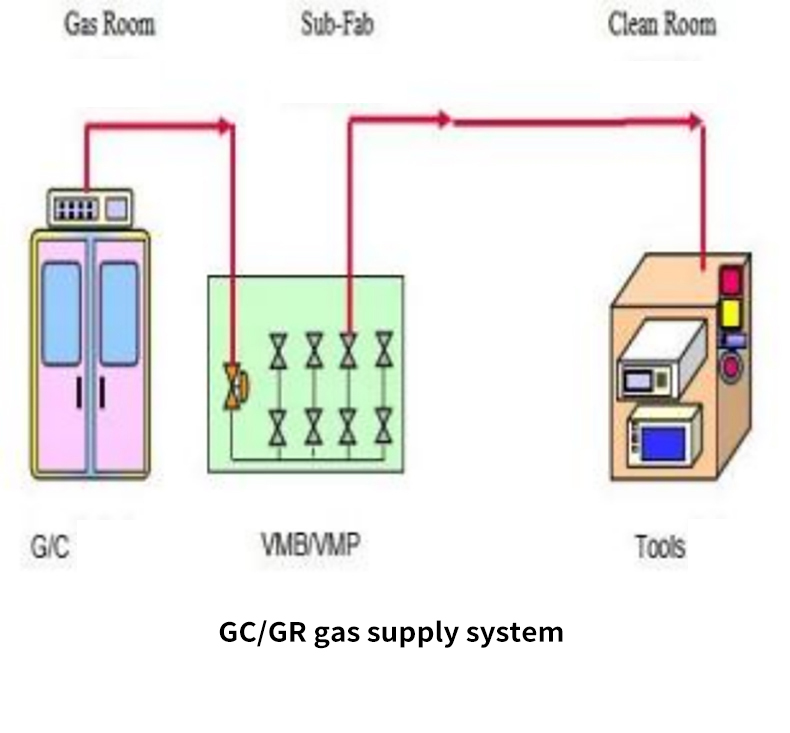

GC/GR Gas Supply System

A GC (Gas Cabinet) is a supply system specifically designed for the supply of flammable, explosive, corrosive, toxic, and other hazardous gases. Its integrated design of "explosion-proof cabinet + high-purity gas flow + automatic switching/purging + multiple safety interlocks" effectively confines high-risk gases while ensuring continuous process downtime and no gas contamination. It is an essential safe gas supply unit for high-end manufacturing applications such as semiconductors, photovoltaics, and biopharmaceuticals.

A GR (Gas Rack) is a delivery system for inert gases. Commonly used in high-end manufacturing plants for semiconductors, photovoltaics, LEDs, biopharmaceuticals, and other industries, it provides an open or semi-open cylinder/tube switching system for the safe, centralized, and continuous supply of inert or low-hazard process gases (N₂, Ar, He, H₂, O₂, CDA, etc.). Compared to a fully enclosed GC (Gas Cabinet), a GR offers a simpler structure, lower cost, and more intuitive operation. It is suitable for non-toxic, non-flammable, and non-corrosive bulk or auxiliary gases and serves as the most common intermediate gas distribution node between the cleanroom, facility, and process.

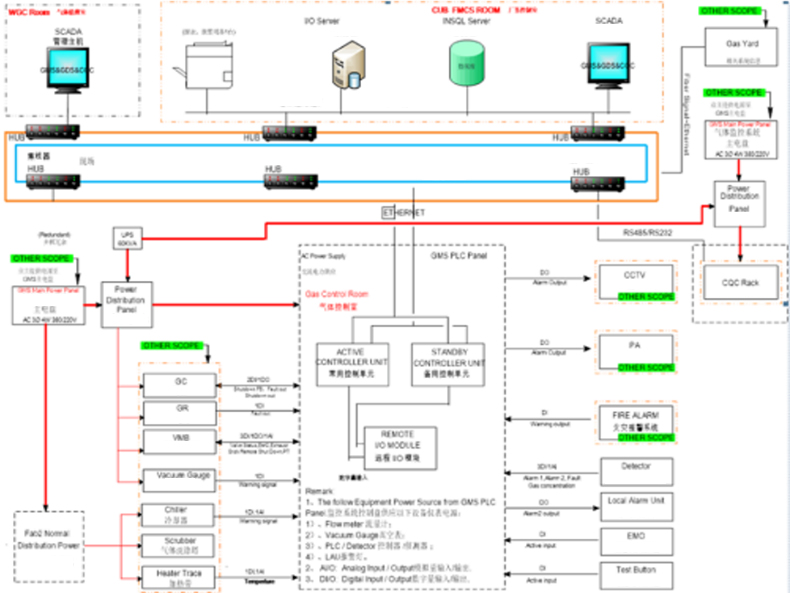

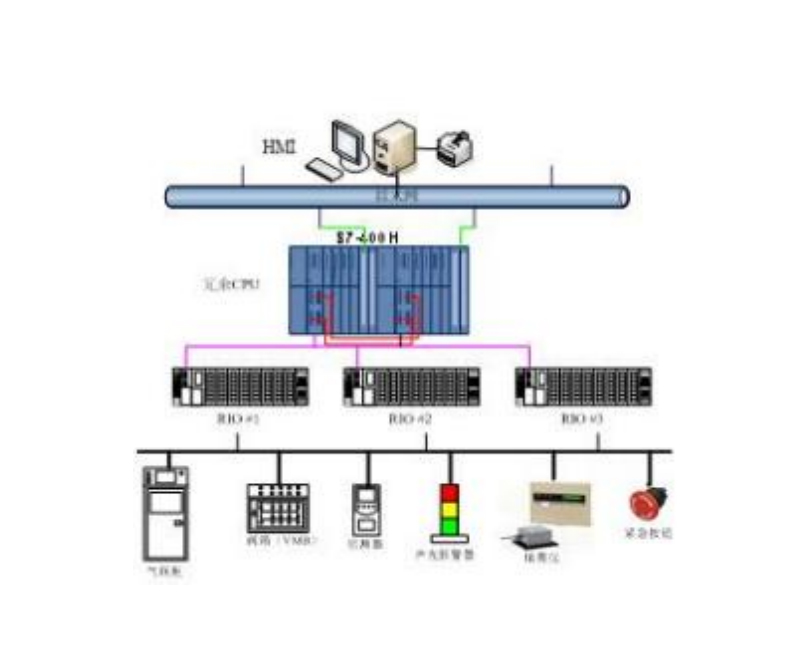

Specialty Gas Monitoring and Detection Systems (GMS, GDS) are critical systems for ensuring the safe and stable operation of specialty gases during storage, transportation, and use.

GMS (Gas Management System): A GMS is a system used to monitor and record the operating status of specialty gas equipment in real time. It utilizes a network of high-precision sensors to monitor key parameters of the gas supply system, such as pressure, flow, and purity.

Functions:

Real-time Monitoring: Monitors parameters such as pressure, temperature, and liquid level in specialty gas cylinders or storage containers.

Gas Distribution Control: Precisely controls gas delivery from storage areas to points of use, regulating valve opening and gas flow.

Quality Monitoring: Gas analyzers are used to measure the purity and impurity content of specialty gases.

Data Logging and Analysis: Records system operating parameters and event information, supporting historical query capabilities.

Remote Control: Supports remote activation of alarm units and shutdown of gas supply equipment.

GDS (Gas Detector System): A GDS is a system used to monitor gas concentrations in the environment in real time and generate alarms. It primarily focuses on gas leak detection and safety alarms.

Functions:

Real-time Monitoring: Gas detectors monitor the gas concentration in the environment in real time.

Alarm Function: When the gas concentration exceeds a preset value, an audible and visual alarm signal is triggered.

Interlocking Control: Can be linked to ventilation systems, sprinkler systems, and other systems to automatically shut off the gas source.

Data Transmission: Supports communication with a host computer or other devices for remote monitoring.

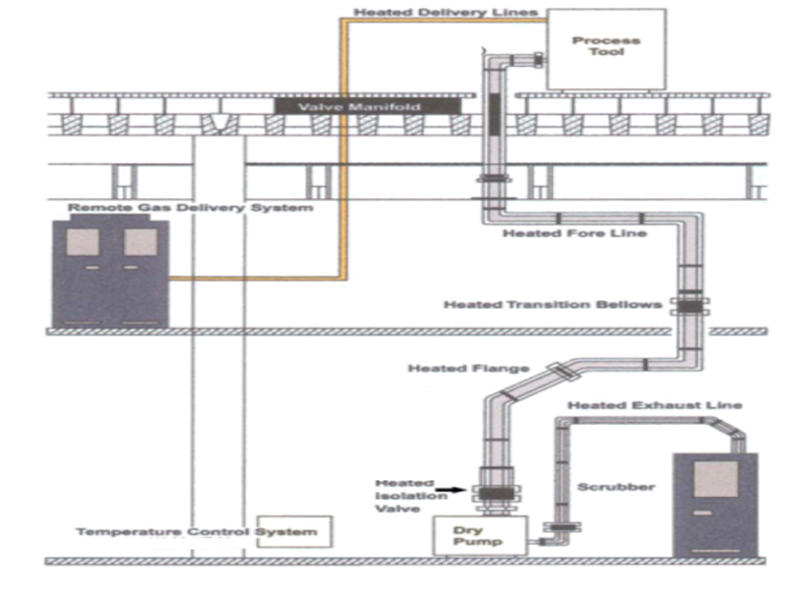

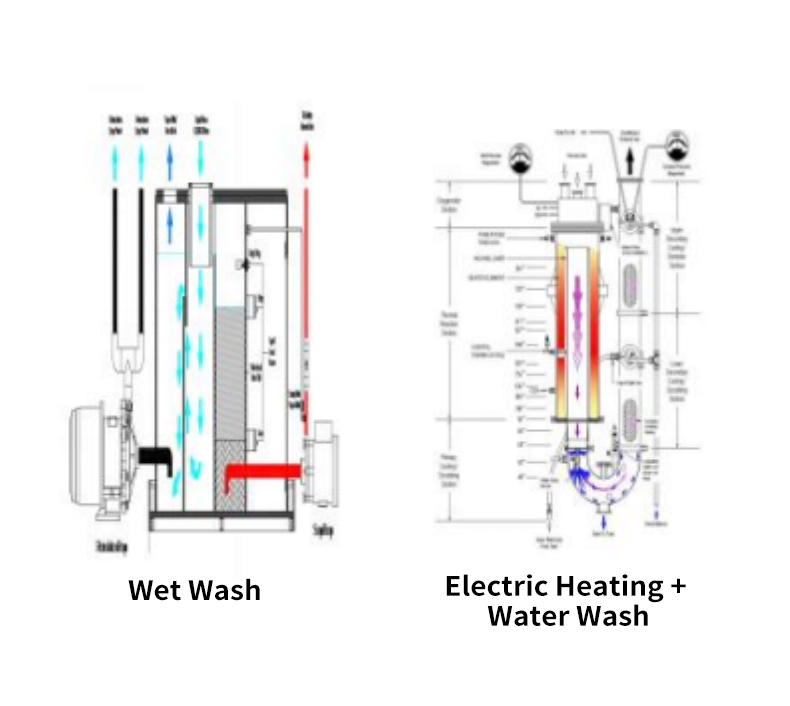

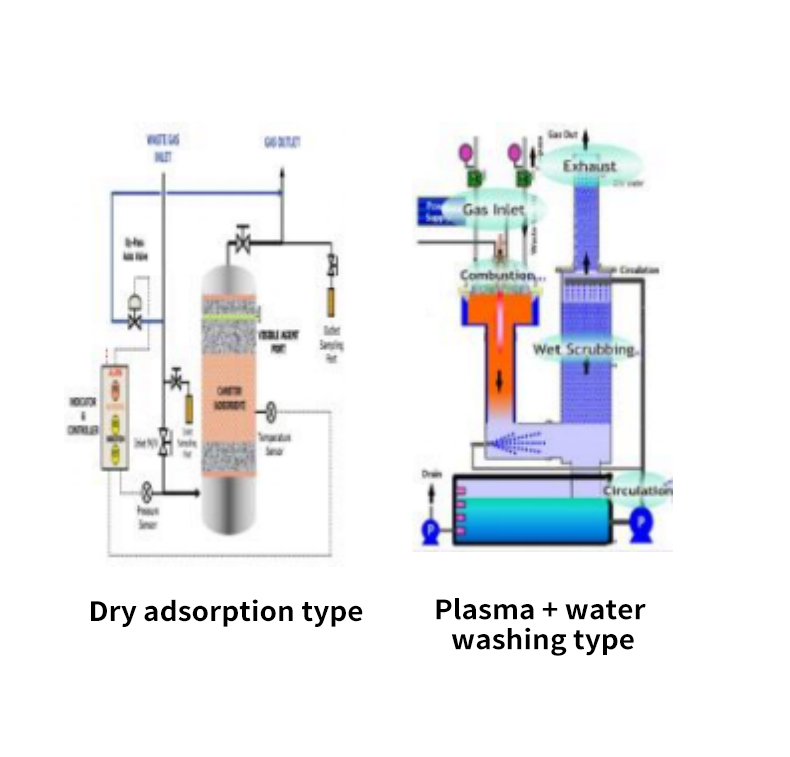

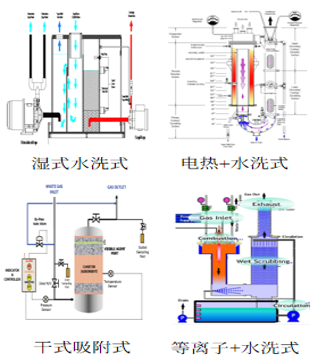

Exhaust Gas Treatment System

This device is used to treat the exhaust and purge gases of flammable, explosive, toxic, and corrosive gases. The treated exhaust gas reaches the specified emission concentration and is discharged into the exhaust duct of the gas-using workshop.

Wet scrubbers utilize neutralizers such as acids and alkalis, and oxidizers (such as potassium manganate (KMnO4)) for absorption. These include porous plate, spray, and jet scrubber types. This method offers lower costs, but its effectiveness against certain gases (such as hydrides) is limited. It is commonly used to remove harmful gases from the air.

Dry Scrubbers: These include adsorption and catalytic absorption methods. The adsorption method utilizes chemicals for redox treatment and is suitable for treating fluorinated compounds that are difficult to hydrolyze or absorb. The catalytic absorption method uses catalysts to promote chemical reactions, improving treatment efficiency.

Combustion + water scrubbing: For high-concentration, large-flow exhaust gas, a combustion scrubber is often used to burn the exhaust gas into compounds that are easy to handle. Here, natural gas is used to directly burn the exhaust gas, which is then further adsorbed and treated by a wet scrubber.

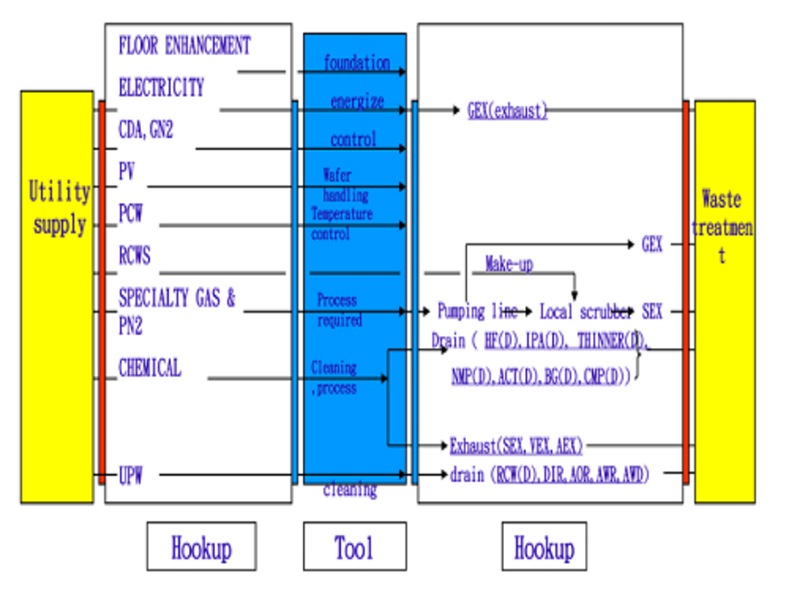

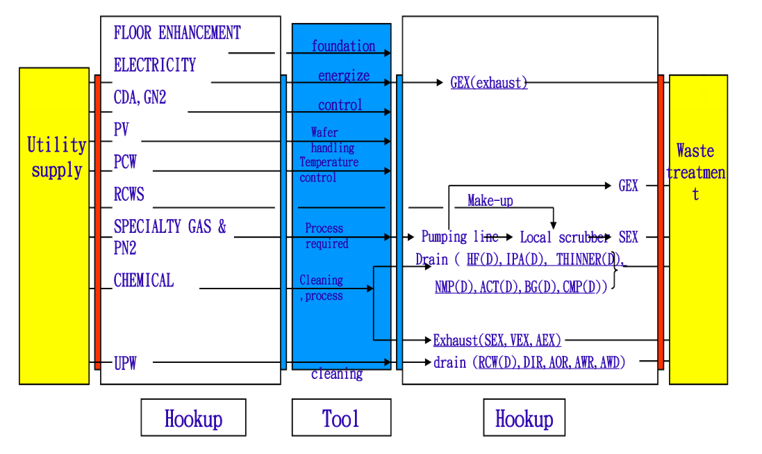

Secondary distribution engineering is the final step in connecting process equipment. The quality of this work directly impacts product quality. This work includes, but is not limited to, specialized engineering for production equipment, including power, process cooling water, gases, chemicals, exhaust, pure water, wastewater, process vacuum tubes, raised floors, and seismic bases.

Features:

Complex and diverse systems, numerous uncertainties, and tight deadlines

Digital design to avoid errors and ensure effective space management

Organized work flow, digitalized and form-based management throughout the entire process

Complex working environment, with effective safety and quality control measures

All construction is based on the preservation of finished products and equipment

Comprehensive third-party testing procedures and acceptance standards