Green computing infrastructure

Green computing power trends

Globally, the urgent demand for green and efficient computing power is becoming increasingly prominent, driving the data center industry to accelerate its transformation towards low-carbon and environmentally friendly directions to meet the challenges of climate change.

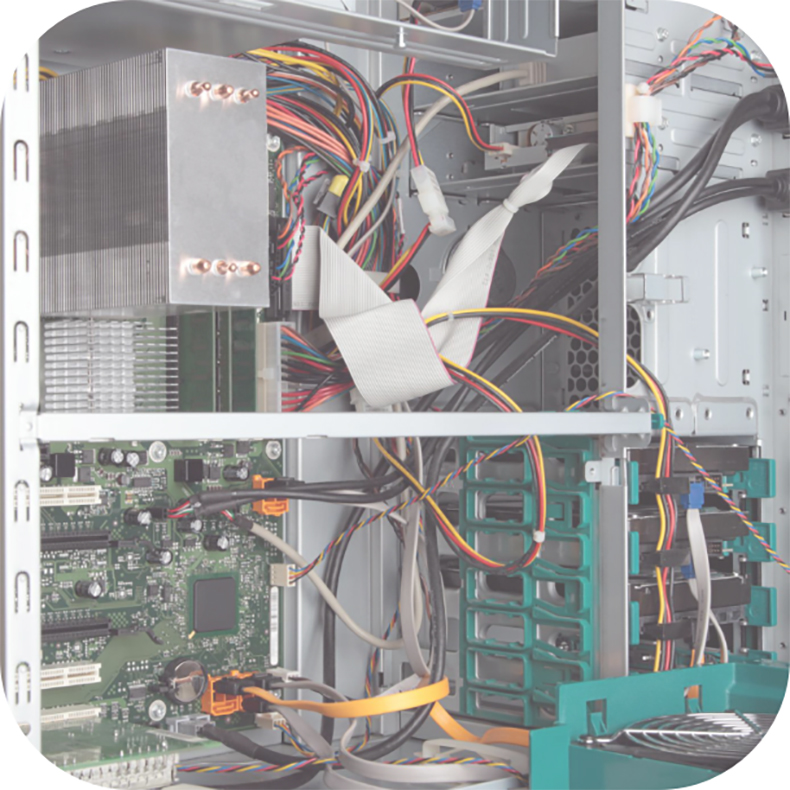

New Challenges in Computing Power Cooling

With the exponential growth of computing power demand, traditional air cooling technology has faced efficiency bottlenecks and is unable to meet high-density deployment requirements, becoming a key factor restricting the development of data centers.

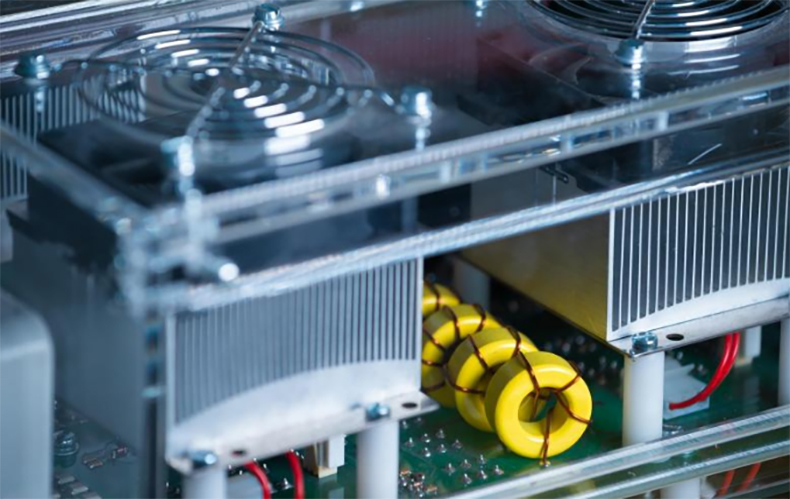

Liquid cooling technology innovation

As the next-generation heat dissipation solution, liquid cooling technology, with its superior heat conduction efficiency and improved space utilization, brings unprecedented heat dissipation innovation to data centers, leading the industry to new heights.

Integrating green technologies

By integrating cutting-edge green technologies such as liquid cooling, new energy, and high-performance computing, the data center has built a perfect ecosystem, contributing positively to the earth's environment and leading a new era of green computing power.

Industry pain points and solutions

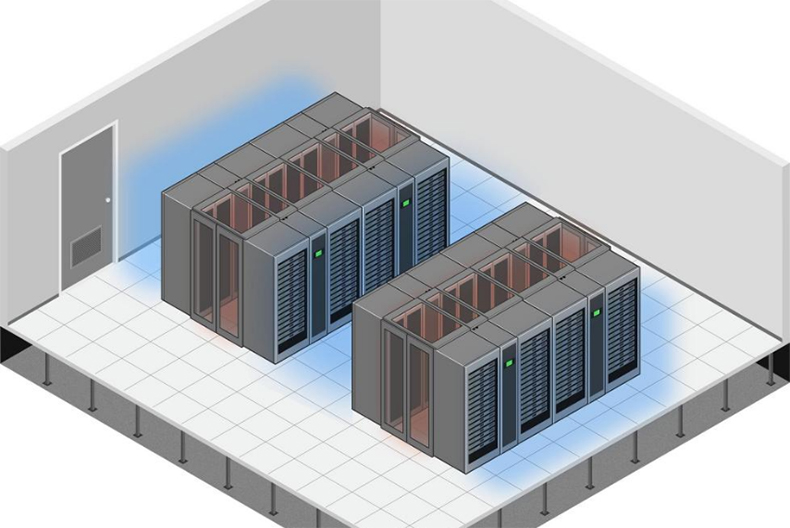

Heat dissipation bottleneck: As the power density of a single cabinet exceeds 20kW, the efficiency limitations of air cooling are becoming increasingly prominent, becoming a key bottleneck restricting the continued expansion of data centers.

High energy consumption: Air conditioning accounts for over 40% of energy consumption, significantly increasing data center operating costs. Meanwhile, the PUE (power usage effectiveness) index far exceeds 1.5, requiring urgent optimization.

Space limitations: The contradiction between high-density deployment and heat dissipation needs is becoming increasingly prominent. It is difficult to effectively dissipate heat in a limited space, which has become another problem restricting the development of data centers.

Solution: Rongke Technology's innovative liquid cooling system precisely solves the problem of low air cooling efficiency, ensuring efficient and stable operation of the data center and injecting strong momentum into computing power development.

We reduce energy consumption through excellent energy efficiency, lowering PUE to below 1.1, effectively alleviating the problem of high energy consumption and promoting the development of green computing power.

We cleverly resolve the contradiction between space and heat dissipation, improve space utilization by more than 30%, and open up a new path for data center development.

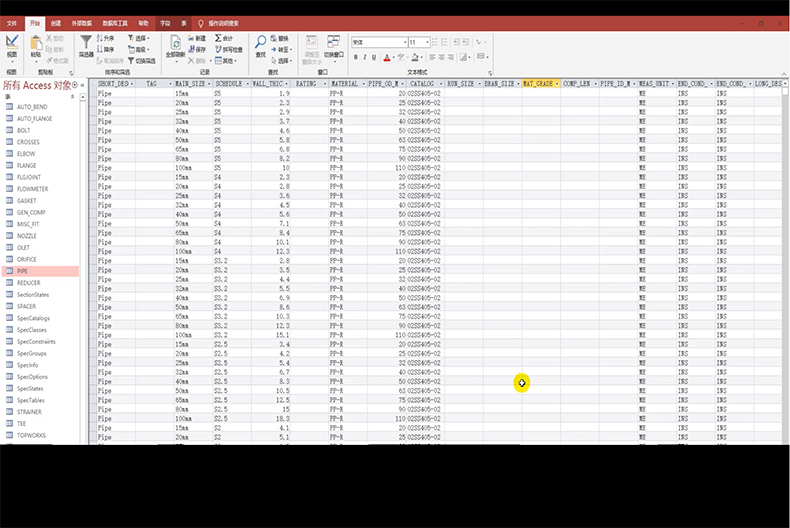

Panoramic Solution for Liquid Cooling System - Digital Design

25594 pipeline (PIPE) data

10717 flange data

7125 Gasket data

3834 bolt and stud (BOLT) data

14950 valve (VALV) data

6715 valve actuator (TOPWOKS) data

10374 Elbow (ELBOW) data

2265 REDUCER data

5849 TEE data

7244 OLET data

9115 other commonly used pipe fittings (MISC-FIT) data

…

More than 1 million geometric and attribute information data have been completed

Panoramic Solution for Liquid Cooling Systems - Modular Architecture

Highly compatible design: The modular architecture adopts a highly compatible design concept to ensure seamless connection between different modules, easily coping with various complex and changing cooling scenarios.

Hot-swappable technology: Rongke liquid cooling system supports hot-swappable technology, which allows modules to be easily inserted or removed during operation without additional downtime for maintenance, thus improving system maintenance efficiency.

Flexible expansion capabilities

The modular architecture offers flexible expansion capabilities. As cooling needs grow, new modules can be easily added to ensure the system maintains continuous high performance and efficiency.

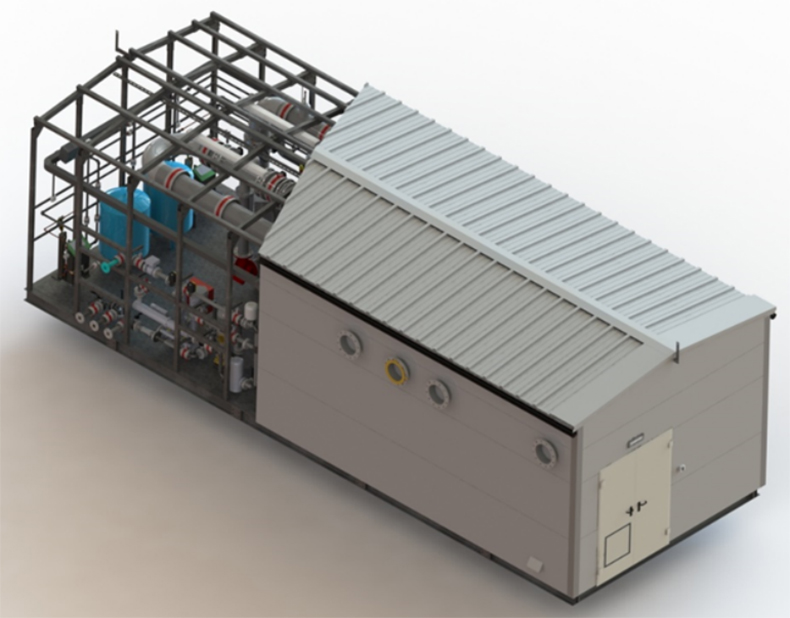

Panoramic solution for liquid cooling system - prefabricated assembly

A. Implementation steps:

1. Modular design

2. Factory modular manufacturing

3. Modular transportation

4. On-site modular assembly

B.Technical advantages:

1. Save space

2. Save construction period

3. Reduce pollution

4. Improve product quality

C.Product Features:

1. Engineering productization

2. Overall prefabrication

3. Efficient and sustainable

4. Single responsibility