Rongke Technology Empowers the Future

The Raycom Data Center Temperature Control and Energy Saving Division , leveraging the capabilities of the Raycom Group, specializes in providing high-efficiency liquid cooling system integration services for data centers and computing centers. This service primarily provides precision machining of liquid cooling system components, research and development and selection of coolants, system integration of the primary and secondary sides of liquid cooling systems, and efficient energy management and energy-saving technologies for data centers.

Positioning: A leading domestic provider of precision parts processing, integration and supporting services.

Leveraging its deep R&D expertise and innovative capabilities, Raycom has meticulously cultivated the field of data center liquid cooling systems, continuously breaking through technological barriers and leading the industry to new heights. Raycom is committed to leveraging liquid cooling technology as its core driving force, collaborating with industry partners and users to create a new era of green, efficient, and sustainable computing power, and to building a new blueprint for an intelligent world.

The company has a Class 10 clean room of 50 square meters, a Class 100 clean room of 1,000 square meters, and a precision machining workshop of 800 square meters. It has over 100 mid- and senior-level technical personnel and is fully equipped with hundreds of production and testing equipment for precision machining, equipment assembly, module production, and other related equipment.

Green computing infrastructure

1. New Challenges in Computing Power Cooling

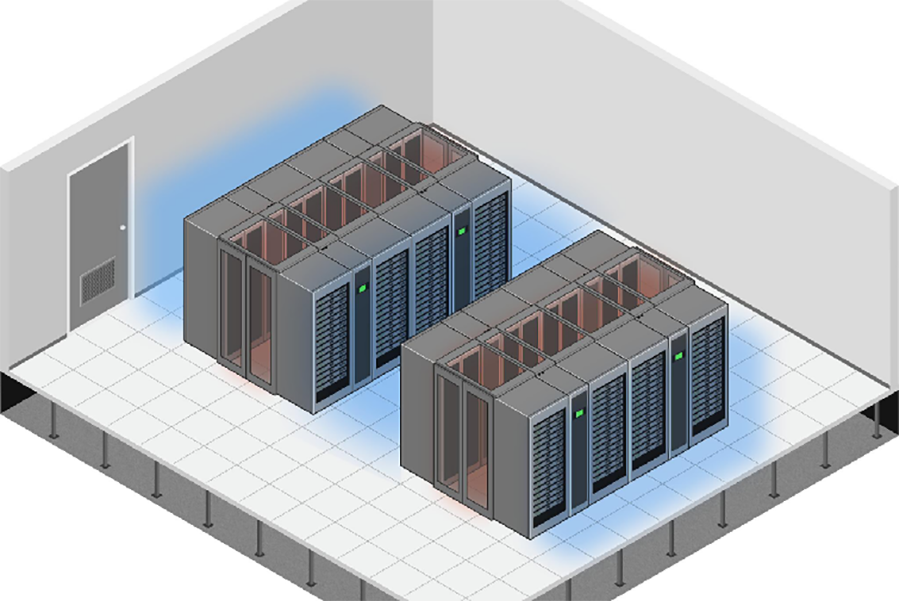

With the exponential growth of computing power demand, traditional air cooling technology has faced efficiency bottlenecks and is unable to meet high-density deployment requirements, becoming a key factor restricting the development of data centers.

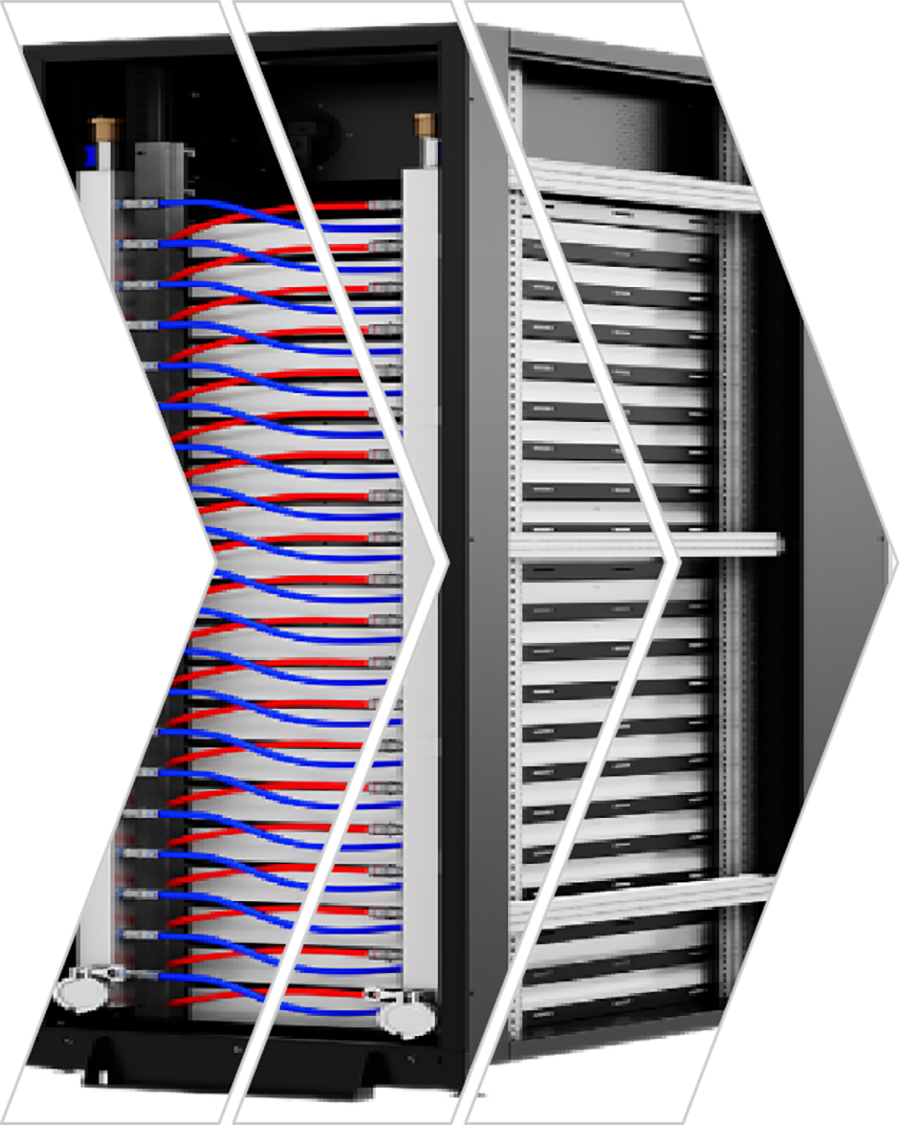

2. Liquid cooling technology innovation

As the next-generation heat dissipation solution, liquid cooling technology, with its superior heat conduction efficiency and improved space utilization, brings unprecedented heat dissipation innovation to data centers, leading the industry to new heights.

3. Green computing power trend

Globally, the urgent demand for green and efficient computing power is becoming increasingly prominent, driving the data center industry to accelerate its transformation towards low-carbon and environmentally friendly directions to meet the challenges of climate change.

4. Integrate green technology

By integrating cutting-edge green technologies such as liquid cooling, new energy, and high-performance computing, the data center has built a perfect ecosystem, contributing positively to the earth's environment and leading a new era of green computing power.

Industry pain points and solutions

Heat dissipation bottleneck

As the power density of a single cabinet exceeds 20kW, the efficiency limitations of air cooling are becoming increasingly prominent, becoming a key bottleneck restricting the continued expansion of data centers.

High energy consumption

Air conditioning energy consumption accounts for over 40%, significantly increasing the operating costs of data centers. At the same time, the PUE (power usage efficiency) index far exceeds 1.5 and urgently needs to be optimized.

Space limitations

The contradiction between high-density deployment and heat dissipation needs is becoming increasingly prominent. It is difficult to effectively dissipate heat in a limited space, which has become another problem restricting the development of data centers.

Solution

Rongke Technology's innovative liquid cooling system precisely solves the problem of low heat dissipation efficiency of air cooling, ensuring efficient and stable operation of data centers and injecting strong impetus into computing power development.

We reduce energy consumption through excellent energy efficiency, lowering PUE to below 1.1, effectively alleviating the problem of high energy consumption and promoting the development of green computing power.

We cleverly resolve the conflict between space and heat dissipation, improving space utilization by over 30% and opening up a new path for data center development.

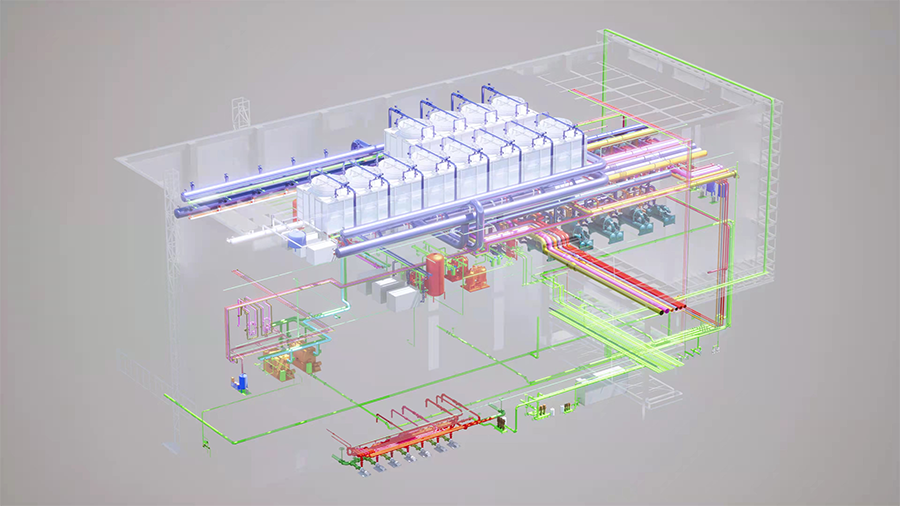

Panoramic solution for liquid cooling system - scheme design

1. Deepening of scheme design

Deepen the design of liquid cooling system solutions to precisely match data center cooling requirements and ensure efficient adaptation. Simultaneously conduct coolant screening, prioritizing both performance and safety, to lay a solid foundation for the liquid cooling system.

2. Cooling strategy optimization

Innovative liquid cooling strategies, such as the use of high-efficiency heat exchange technology, improve heat dissipation efficiency and significantly reduce PUE. Furthermore, the cooling liquid circulation path is optimized to reduce flow resistance and ensure stable system operation.

3. Environmental adaptability assessment

Comprehensively evaluate the liquid cooling system's adaptability to different environmental conditions, such as temperature and humidity, to ensure the system maintains good performance in various data center environments and meets long-term stable operation requirements.

4. Cost control strategy

Implement cost control strategies and reduce initial investment and operation and maintenance costs of liquid cooling systems through refined management. At the same time, explore recovery mechanisms, such as recycling and reusing coolant, to further reduce overall costs.

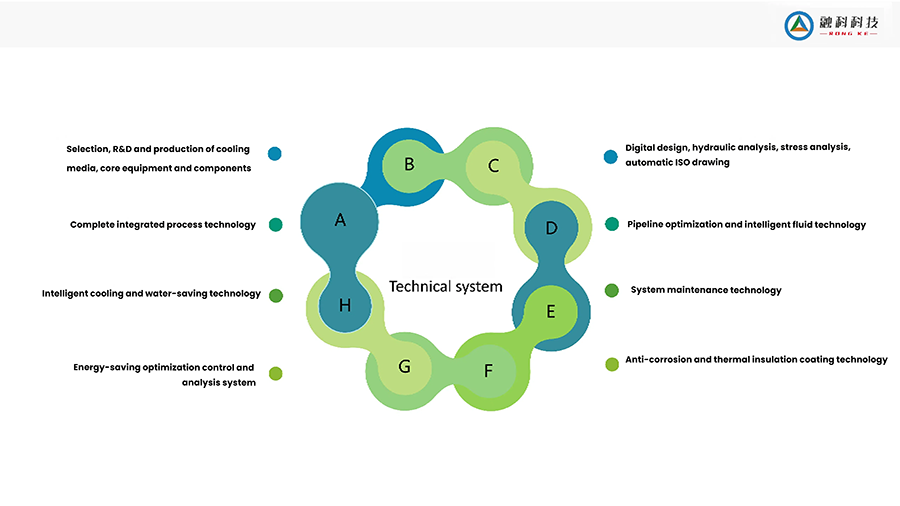

Panoramic Solution of Liquid Cooling System - Core Technology

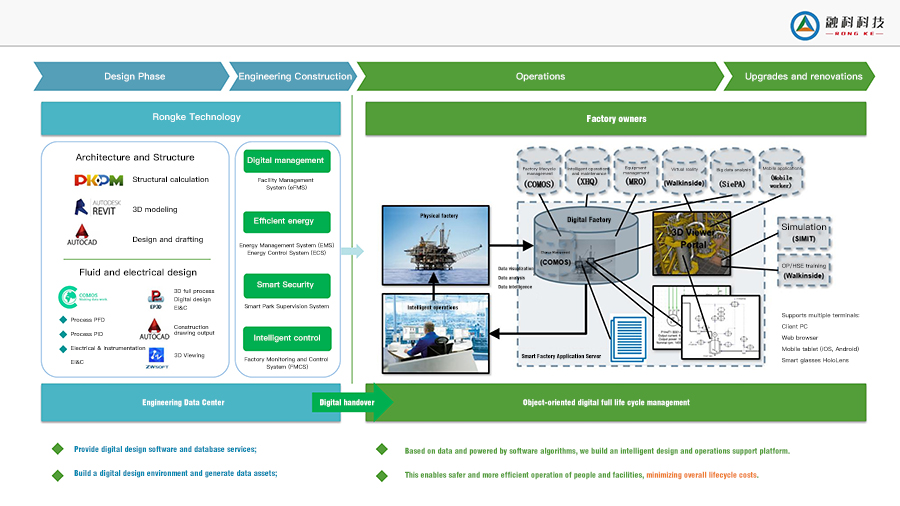

Panoramic Solution for Liquid Cooling Systems - Co-creating Digital Assets and Intelligent Facilities

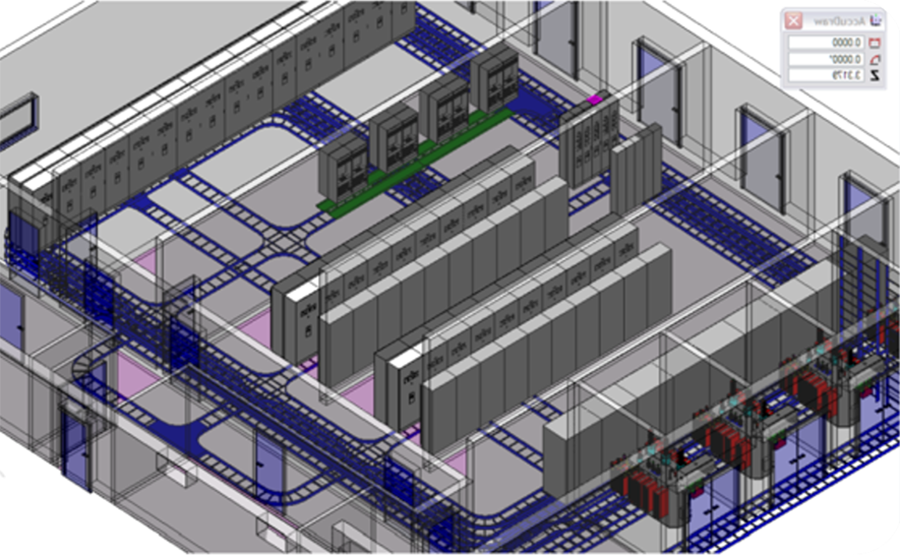

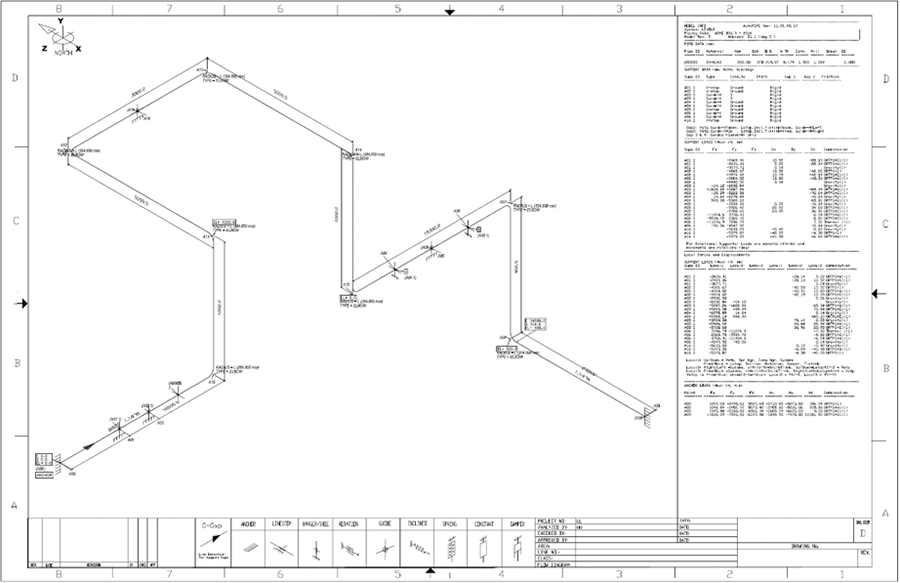

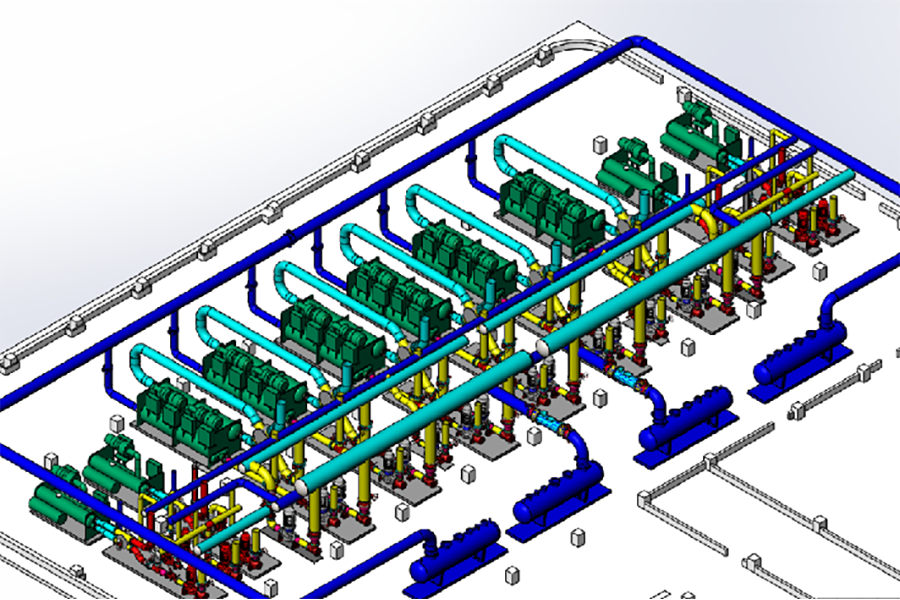

Panoramic Solution for Liquid Cooling System - Digital Design

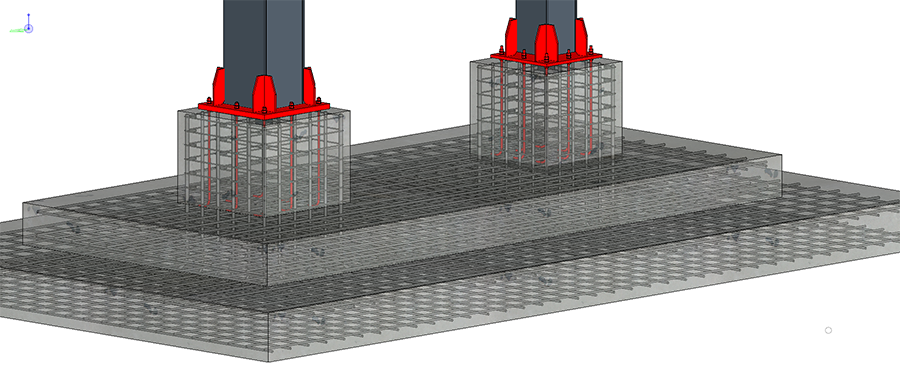

civil engineering

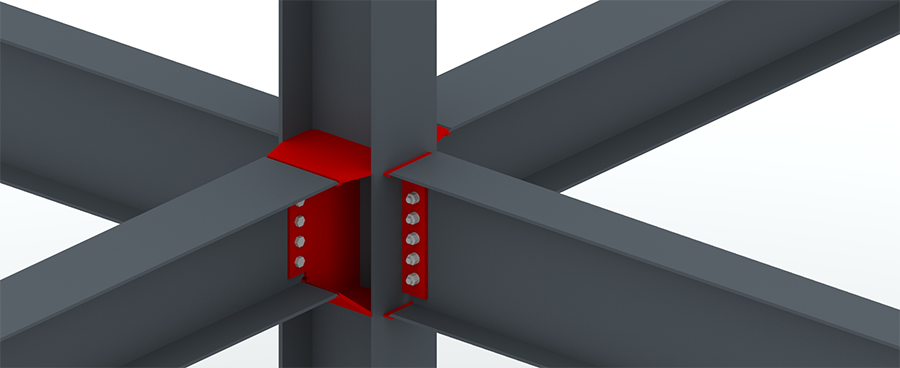

Electrical Engineering

Equipment and piping engineering

Include:

Pipeline hydraulic analysis

Pipeline stress analysis

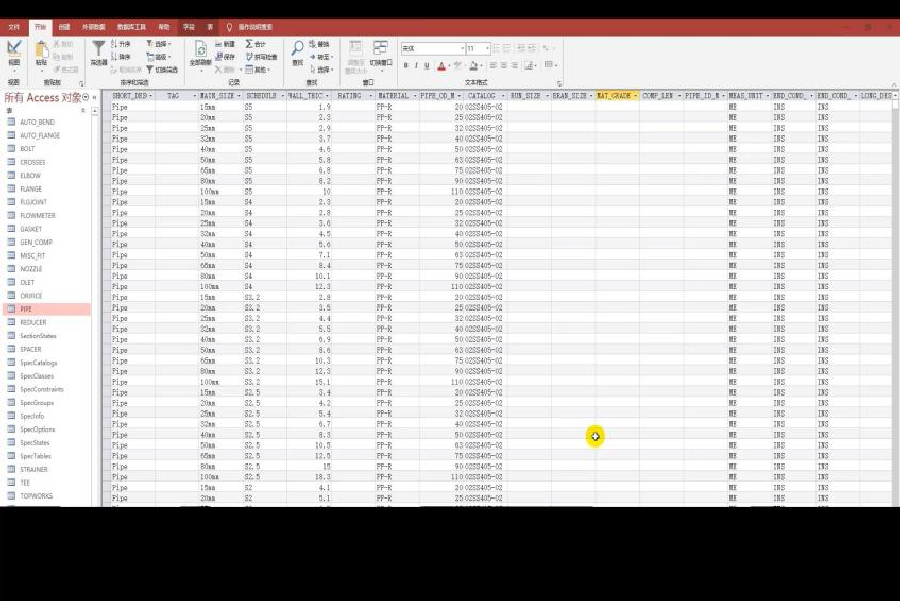

Panoramic Solution for Liquid Cooling System - Digital Design

25,594 pipeline (PIPE) data

10717 flange data

7125 Gasket data

3834 bolt and stud (BOLT) data

14950 valve (VALV) data

6715 valve actuator (TOPWOKS) data and 10374 elbow (ELBOW) data

2265 REDUCER data

5849 TEE data

7244 OLET data

9115 other commonly used pipe fittings (MISC-FIT) data

…

More than 1 million geometric and attribute information data have been completed

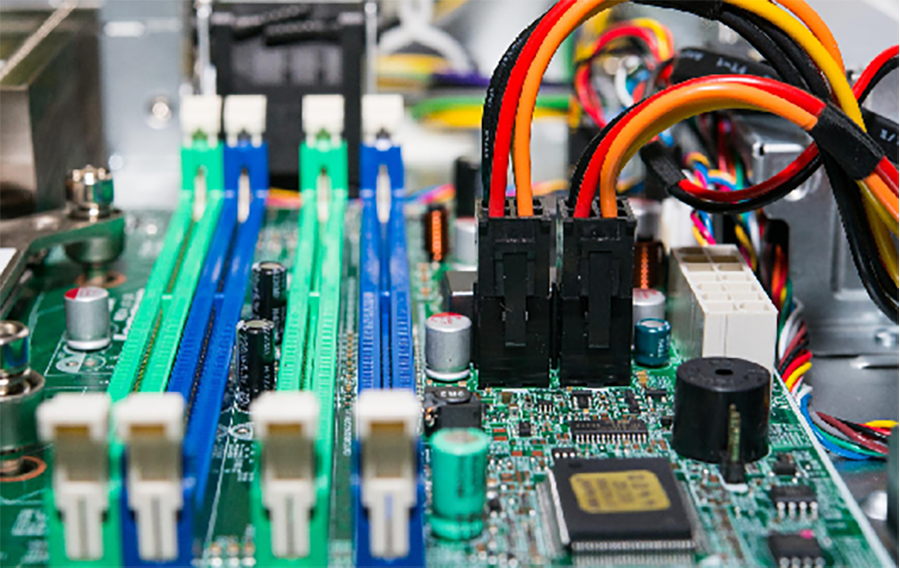

Panoramic Solution for Liquid Cooling Systems - Modular Architecture

Highly compatible design

The modular architecture adopts a highly compatible design concept, ensuring seamless connection between different modules and easily coping with various complex and changing cooling scenarios.

Hot-swap technology

Rongke liquid cooling system supports hot-swappable technology, allowing modules to be easily inserted or removed during operation without additional downtime for maintenance, thus improving system maintenance efficiency.

Flexible expansion capabilities

The modular architecture offers flexible expansion capabilities. As cooling needs grow, new modules can be easily added to ensure the system maintains continuous high performance and efficiency.

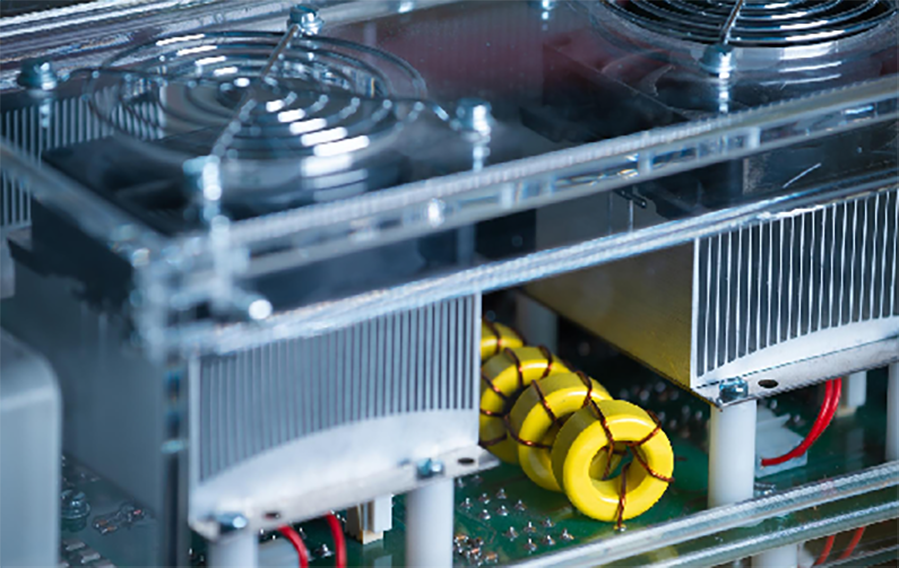

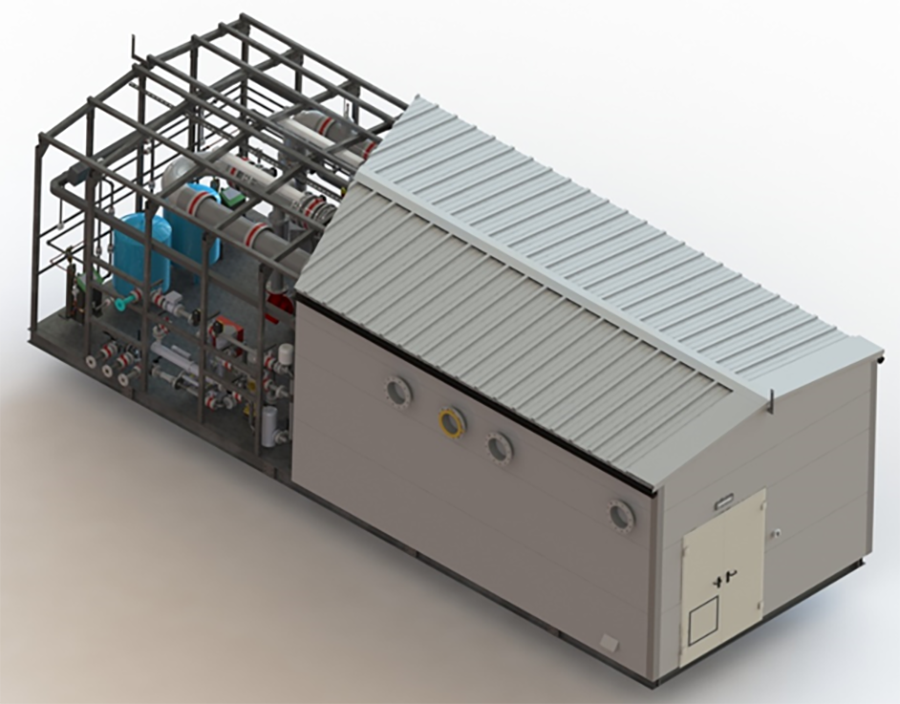

Panoramic solution for liquid cooling system - prefabricated assembly

A. Implementation steps:

1. Modular design

2. Factory modular manufacturing

3. Modular transportation

4. On-site modular assembly

B.Technical advantages:

1. Save space

2. Save construction period

3. Reduce pollution

4. Improve product quality

C. Product Features:

1. Engineering productization

2. Overall prefabrication

3. Efficient and sustainable

4. Single responsibility

Panoramic solution for liquid cooling system - prefabricated assembly

Factory prefabrication and preinstallation

Cement foundation prefabrication

Special car point-to-point transportation

Facade decoration and beautification

Combined boxes, waterproofing, internal pipeline connection

On-site professional lifting

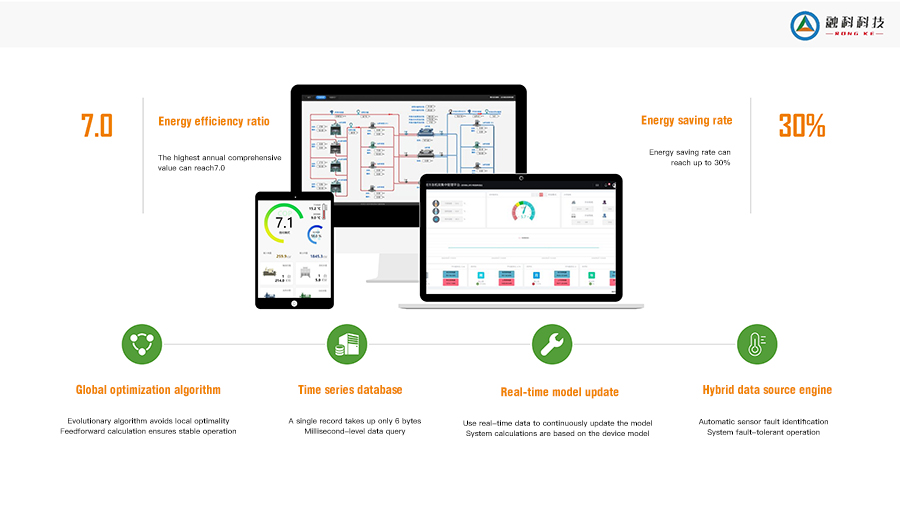

Panoramic Solution for Liquid Cooling Systems - Intelligent Monitoring

AI predictive maintenance

The intelligent monitoring system integrates advanced artificial intelligence algorithms, which can intelligently predict equipment failures, perform maintenance in advance, effectively avoid unexpected downtime, and ensure stable system operation.

Energy efficiency optimization management

Through real-time data analysis and mining, intelligent monitoring helps to accurately control and optimize energy efficiency distribution, ensuring that the data center operates at the best energy efficiency and reducing operating costs.

Remote monitoring and early warning

Intelligent monitoring enables all-weather remote monitoring, instantly pushes early warning information, reduces on-site inspection costs and time, while enhancing safety and ensuring that problems are responded to quickly.

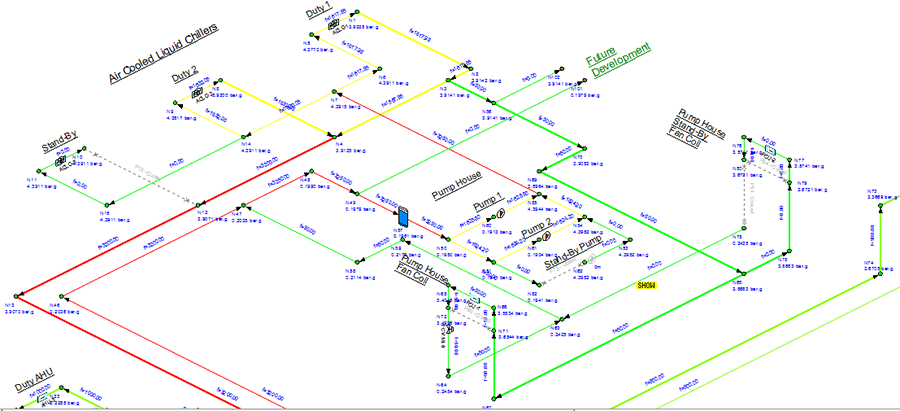

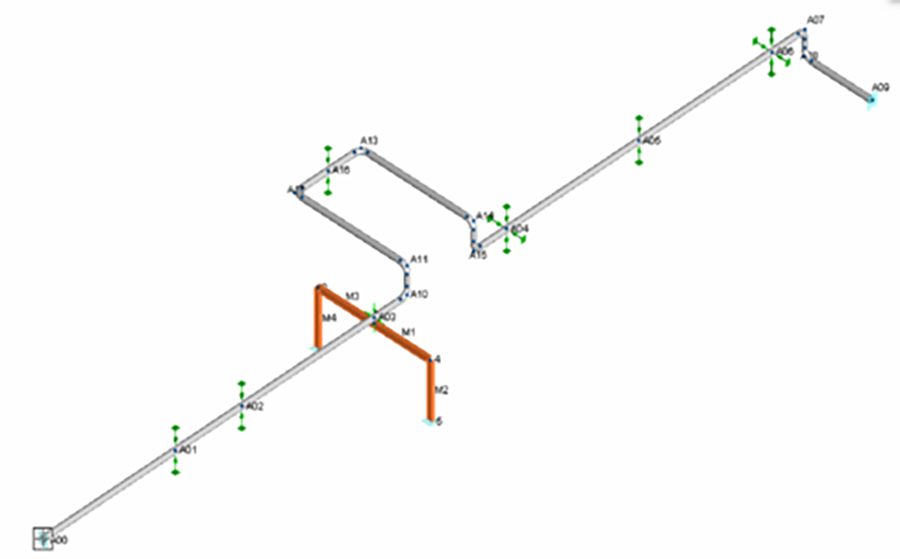

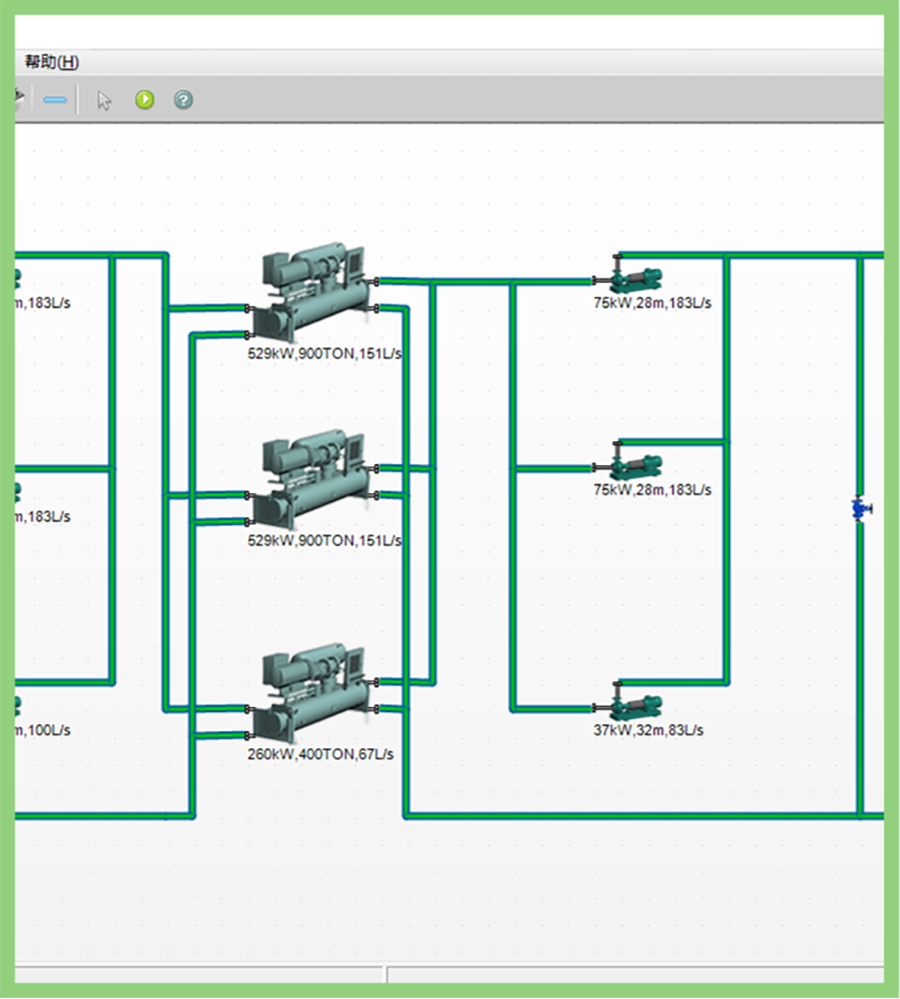

Panoramic Solution for Liquid Cooling Systems - System Simulation

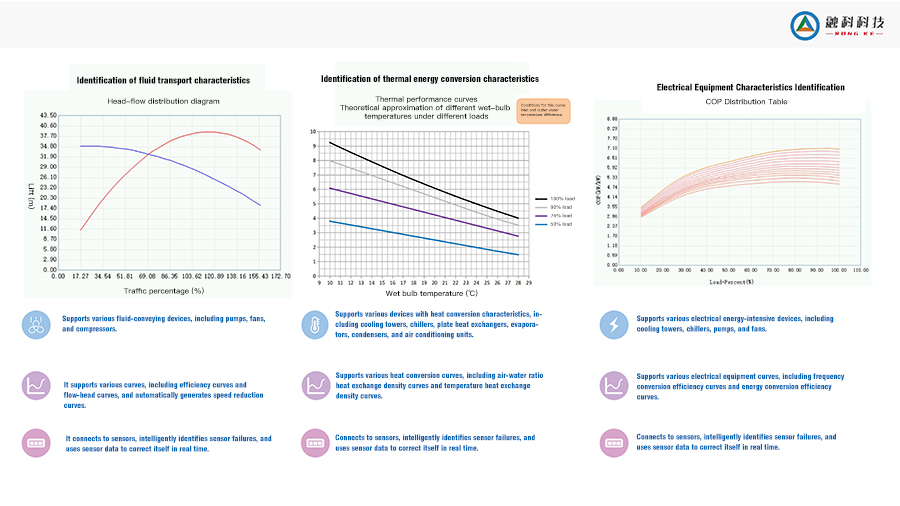

Use self-developed simulation tools to conduct 8,760 hours of multi-dimensional simulation throughout the year.

The independently developed Simulator tool can provide 8,760 hours of comprehensive simulation throughout the year for high-efficiency cooling station design, including key indicators such as load, impedance, and equipment operation, providing designers with the most convincing selection results.

While pursuing high-efficiency design, we clearly understand the economic significance of each measure to achieve optimal PUE results. This system has achieved a PUE of 1.08 in previous projects, and after tuning with this AI system, it will ultimately reach the designed value of 1.046.

1. Load simulation

Support for multiple building types

Support various cooling needs

Obtain load characteristics from actual projects

2. Impedance simulation

Support standard impedance coefficients

Support two-way valve regulation simulation

3. Energy efficiency simulation

Support equipment combinations under different loads

Supports efficient control algorithm simulation

Panoramic Solution for Liquid Cooling Systems - Algorithm Control

Panoramic Solution for Liquid Cooling Systems - Digital Twin