-

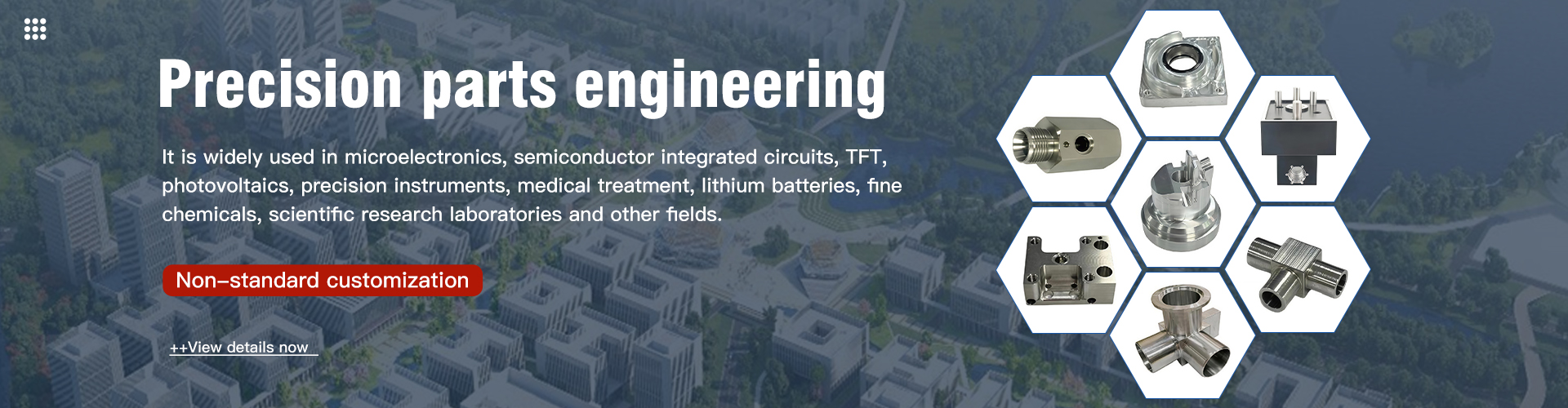

Precision Parts Engineering

Rongke Precision Manufacturing (Guangdong) Co., Ltd., a wholly-owned subsidiary of Jiangsu Rongke Equipment Technology Co., Ltd. (Brand: Rongke Technology), was established in 2018. Formerly known as the Gasification Equipment Division of Rongke Technology, the company primarily provides customized manufacturing of distribution equipment for specialized gas and chemical systems. These equipment is widely used in fields such as microelectronics, semiconductor integrated circuits, TFTs, photovoltaics, precision instruments, medical devices, lithium batteries, fine chemicals, and research laboratories.

Send Email Details

Over the years, its business scope has expanded to include three main business groups: precision component processing, integrated module and proprietary equipment manufacturing, and process equipment refurbishment and modification.

In 2024, a new production base covering over 10,000 square meters will be constructed in Chashan, Dongguan. The facility will include a 50-square-meter Class 10 cleanroom, a 500-square-meter Class 100 cleanroom, and an 800-square-meter precision machining workshop.

The company employs over 100 mid- and senior-level technicians and is equipped with hundreds of high-precision production and testing equipment, including automatic welding machines, five-axis testing instruments, lathes, milling machines, four- and five-axis CNC machining centers, height gauges, profilometers, roughness gauges, and 2D and 3D 3D machines.

Build a foundry for precision manufacturing for domestic semiconductor, medical, optical and other industries, benchmarking against TSMC's model. -

Gas Engineering

The Gas Engineering Division is dedicated to the construction and research of gas delivery systems for high-tech factories, providing customers with stable, safe, reliable, and environmentally friendly gas supply systems. Leveraging the Shanghai Electronic Engineering Design Institute and Rongke Technology's five regional operations centers across China, the Division serves vibrant economic regions such as South China, the Beijing-Tianjin-Hebei region, Central China, East China, and Southwest China. Key design and management personnel are drawn from renowned gas companies and design institutes both domestically and internationally. Professional system integration design is supported by standardized operational instructions, rigorous review procedures, and drawing control. Based on digital design and execution control, utilizing 3D design tools such as UG/SolidWorks/ProE, the Division provides digital full-lifecycle service and delivery for projects.It can safely, automatically and stably transport flammable, toxic or corrosive gases such as SiH₄, NF₃, NH₃, N₂O and HCl.

Send Email Details -

Intelligent Engineering

The Intelligent Business Group, established in 2012, comprises over 120 professional engineers, including core members with over 15 years of industry experience. They possess extensive experience in consulting, design, key equipment manufacturing, and integrated implementation of intelligent systems for electronics industrial plants. We have served over 100 clients and over 500 projects.

Send Email Details

We are committed to providing customers with advanced intelligent facilities. We have participated in the development of numerous national and industry specifications and standards, and independently developed systems such as the "Facility Management System (Intelligent Operation and Maintenance)," "Plant Energy Management System," and "Refrigeration Station Energy Conservation Control System (MPCS)" to improve customer management efficiency and energy utilization.

Main business areas include intelligent facility and energy-saving design consulting, FMCS and automation system integration, intelligent facility systems, energy-saving control systems, smart campuses, communications and security systems, and integrated card systems. We uphold a business philosophy of honesty, integrity, and quality, prioritizing our customers and striving to build exceptional intelligent factories. -

Temperature Control And Energy-Saving Engineering

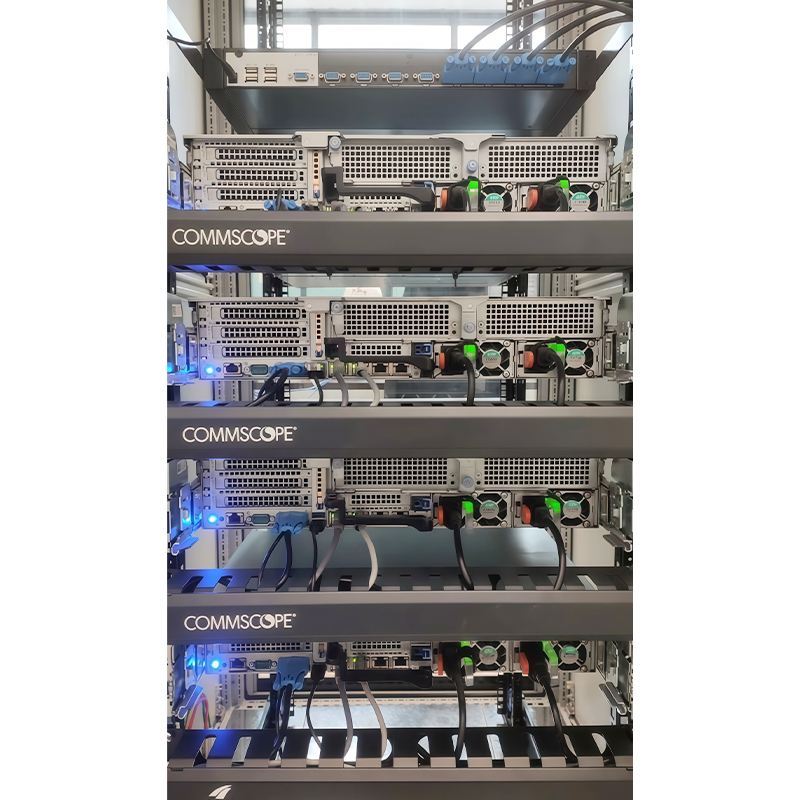

The Raycom Data Center Temperature Control and Energy Saving Division, leveraging the comprehensive capabilities of the Raycom Group, specializes in providing high-efficiency liquid cooling system integration services for data centers and computing centers. This division primarily provides precision machining of liquid cooling system components, coolant research and selection, system integration of the primary and secondary sides of liquid cooling systems, and efficient energy management and energy-saving technologies for data centers.

Send Email Details

Positioning: A leading domestic provider of precision component processing, integration, and supporting services.

Leveraging its deep R&D expertise and innovative capabilities, Raycom has meticulously cultivated the field of data center liquid cooling systems, continuously breaking through technological barriers and leading the industry to new heights. Raycom Technology is committed to leveraging liquid cooling technology as its core driving force, collaborating with industry partners and users to create a new era of green, efficient, and sustainable computing power and build a new blueprint for an intelligent world.

The company boasts a Class 10 cleanroom of 50 square meters, a Class 100 cleanroom of 1,000 square meters, and an 800-square-meter precision machining workshop. With over 100 mid- and senior-level technicians, the company is equipped with hundreds of pieces of comprehensive production and testing equipment for precision machining, equipment assembly, module production, and other related production and testing equipment.